Topic of your interest

"On-demand" inactivation

Material & Umwelt Press releases 12/01/2021

Perhaps you are familiar with the dilemma: you want to protect the environment as well as the health of your employees, but sometimes have to pay a high price for it. For example, the continuous reduction in the use of isopropanol in fountain solution circuits over the past few years has had a positive effect both ecologically and in terms of health. On the other hand, many offset presses are suffering from increased contamination with microorganisms because the alcohol's disinfecting effect can no longer develop to its full extent. This effect is further intensified because manufacturers of fountain solution concentrates are steadily reducing the antimicrobial agents they contain – also for ecological reasons.

This problem was the motivation for Fogra to adopt a method used in medical technology and, by analogy, to look for a completely new way within the framework of a current research project: instead of “completely or not at all”, antimicrobial active substances should in future only be released to the extent that they are required for their purpose: “on demand”!

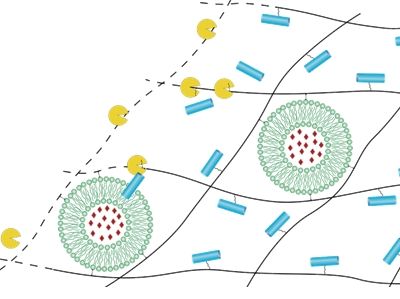

The idea is that a hydrogel network is laid out like a fishing net in the fountain solution reservoir. Microcapsules sit on the meshes of this “net”, which are filled with a corresponding active ingredient and remain sealed as long as the contamination is low.

The microorganisms present in the fountain solution permanently secrete enzymes. If the degree of contamination and thus the enzyme concentration exceeds a threshold value, the capsules open and the antimicrobial agent escapes. The microbial contamination is reduced accordingly via a cascade-like microbiological reaction.

Within the framework of the research project, several challenges have to be overcome: The capsules have to be constructed in such a way that they securely retain the active ingredients and do not further influence the printing process after opening. The network and anchoring of the capsules must be constructed in such a way that they remain stable under the conditions of a slightly acidic fountain solution circuit. The geometry of the hydrogel must also be optimised to ensure good flow on the one hand and to provide a sufficiently large surface area for the capsules on the other. Last but not least, the aim is to produce the hydrogel network as cost-effectively as possible using the 3D printing process.

If we can overcome these challenges, printers can leave the dilemma behind and reduce antimicrobial agents to the minimum necessary.

Are you interested in such innovative topics? Then simply get in touch with us!