Topic of your interest

The research area covers the properties of individual materials (e.g. printing inks, substrates) and their behaviour in the printing process (e.g. curing, change of properties due to the printing process) as well as the interaction of individual components (e.g. adhesion, emulsion formation). Furthermore, environmental compatibility and energy optimisation are important topics.

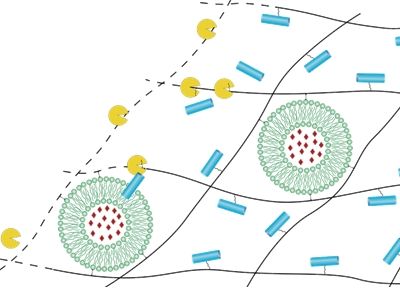

Monitoring and decontamination of fountain solution circuits

Materials & Environment 03/27/2024

Process developent for monitoring and minimising microbial contamination in the fountain solution cycle on the basis of AIE active photosensitisers.

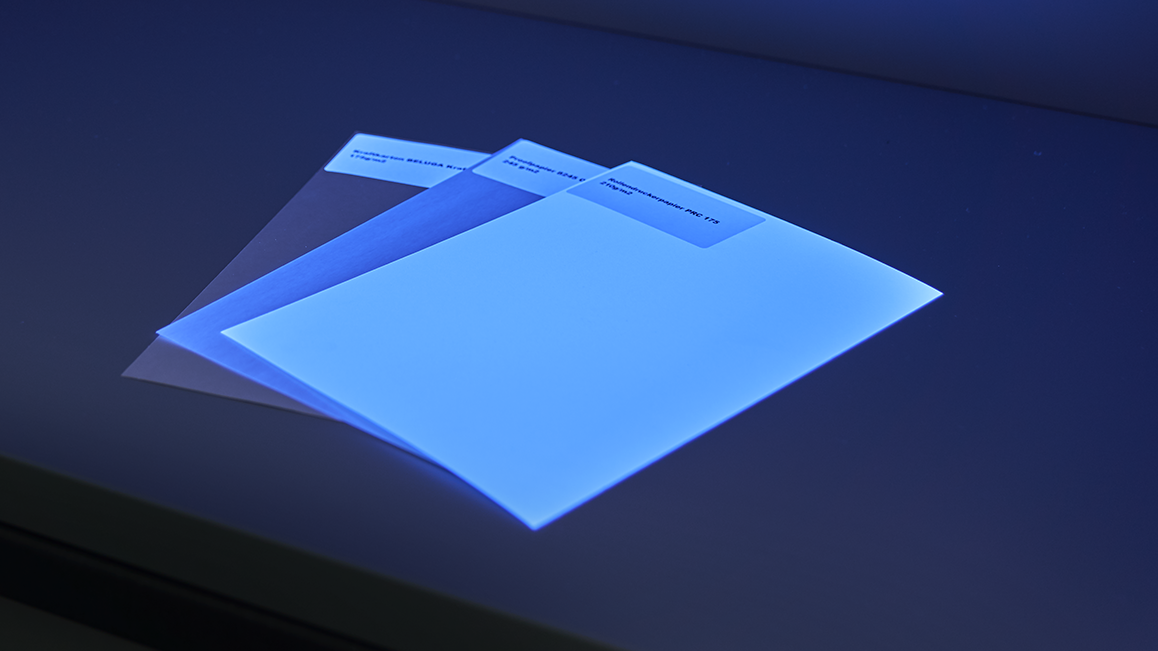

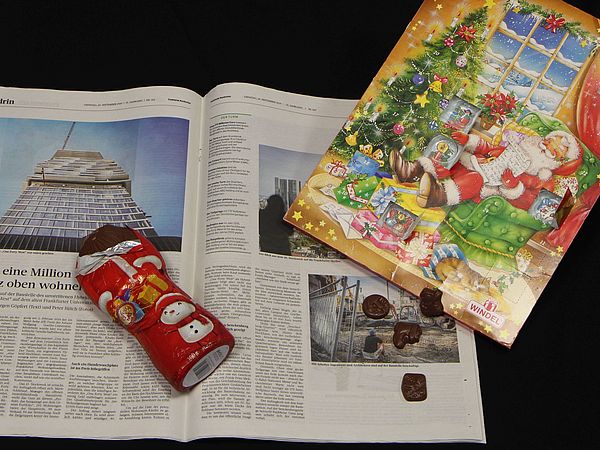

Printing standard for seven-colour offset packaging printing

Offset printing 11/30/2023

The aim is to characterise OGV printing inks, folding boxboard and label papers on the market using laboratory techniques.

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/1/csm_fogra-heatset_8f991b0f76.jpg)

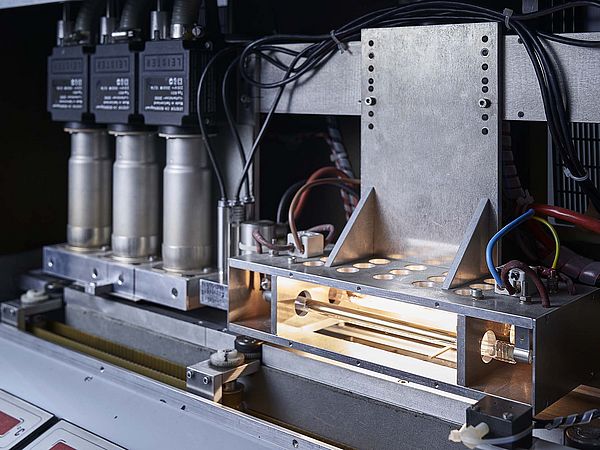

Increased economic efficiency and sustainability of print production with heatset offset presses through independence from natural gas

Offset printing 01/01/2023

The research project is intended to help make print production with heatset offset presses more economical and sustainable.

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/3/csm_fogra-papierstapel_ca2398c293.jpg)

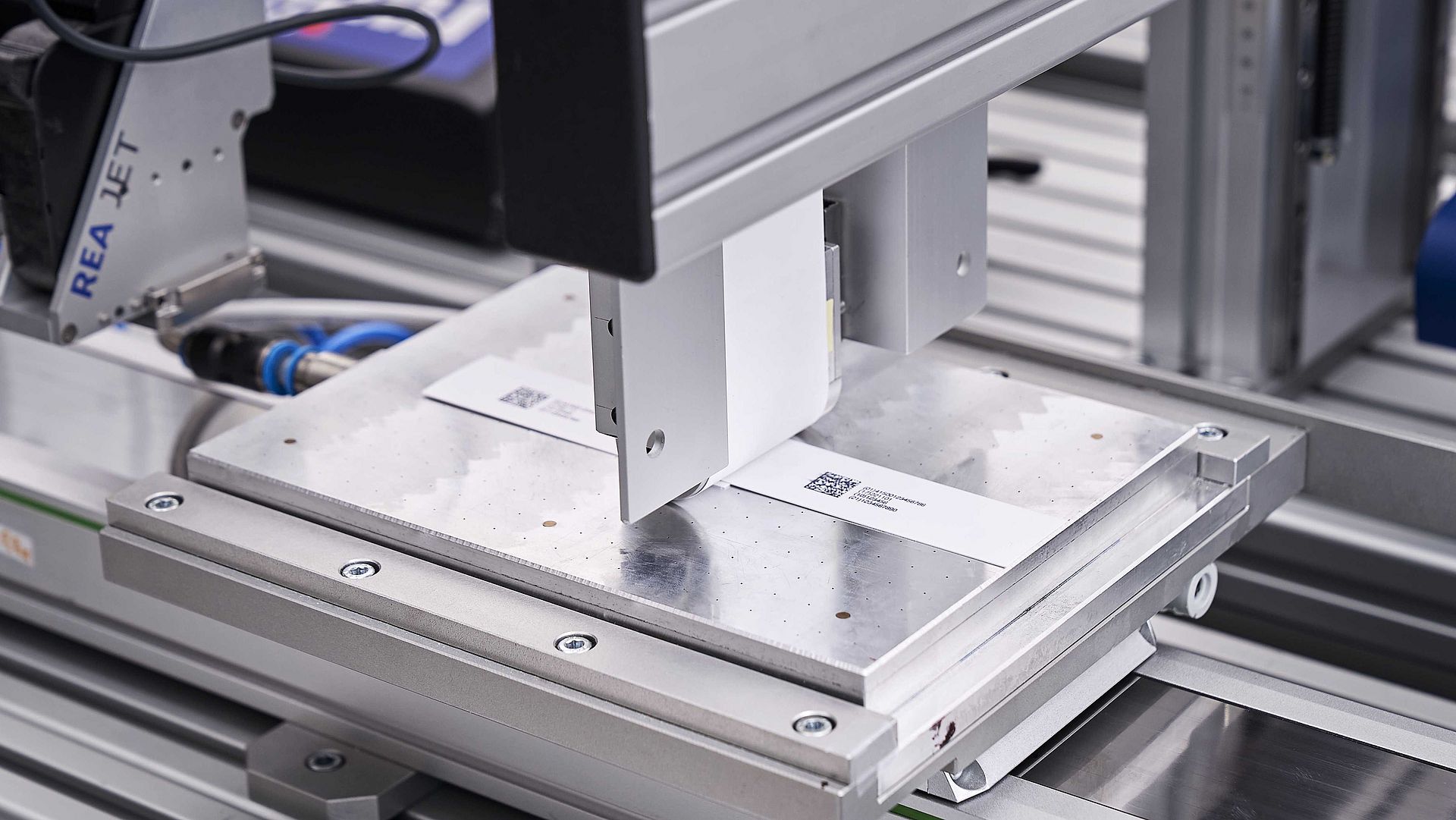

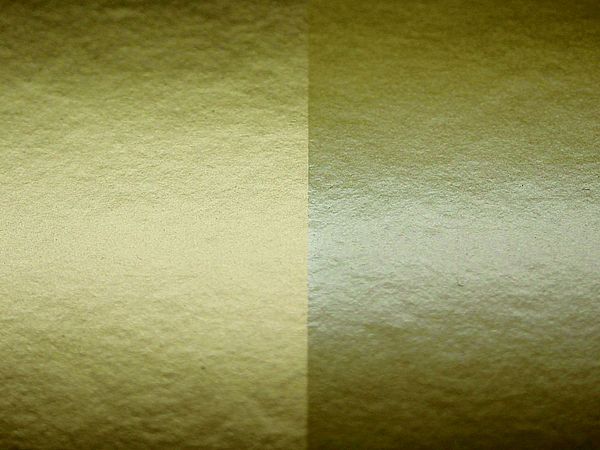

Mackle and CO2 savings through paper-dependent pre-adjustment of sheet-fed offset presses

Offset printing 08/31/2022

The aim is to establish a new paper characteristic value that allows to predict the expected solid tone densities and tone value increases.

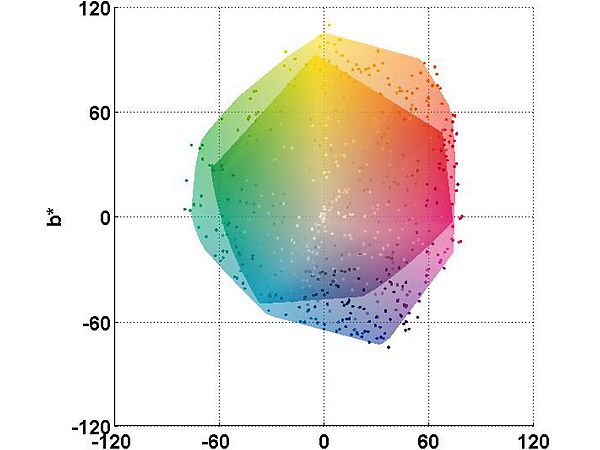

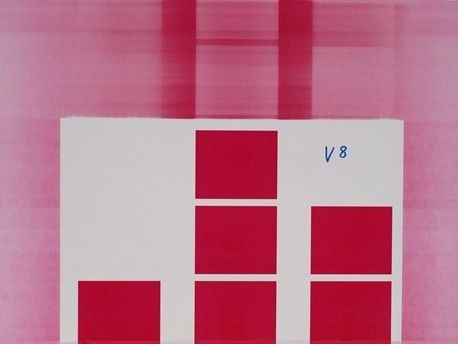

Visual and metrological characterization of metallic effects to increase process reliability in packaging printing

Prepress technology 06/01/2022

The aim is to clarify which properties in human perception are responsible for the expression of the metallic effect.

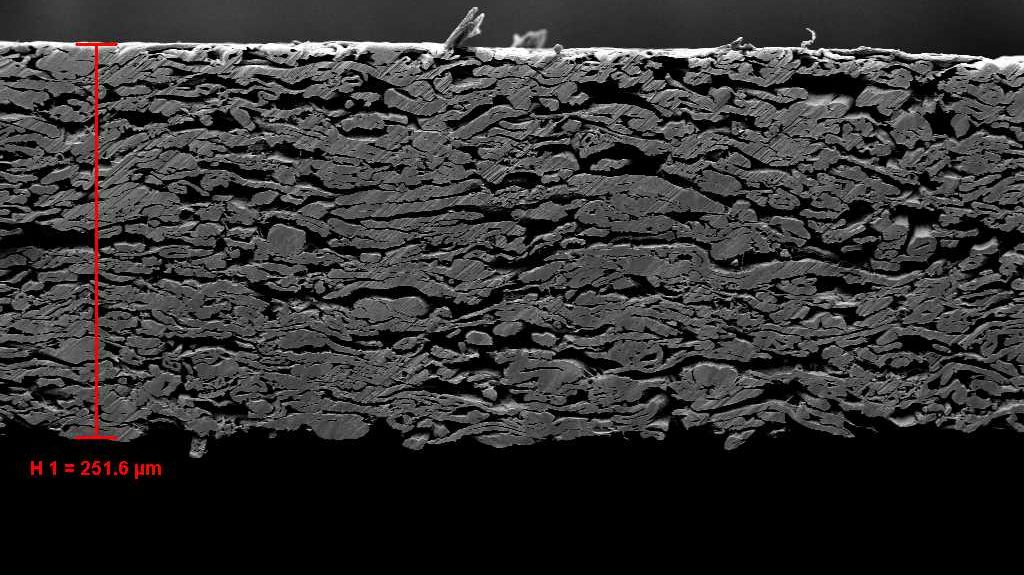

Material compatibility and deinking of mineral oil free Coldset inks

Offset printing 03/01/2021

The aim is to improve the deinkability of mineral oil-free newspaper inks and to establish a new reference set for the swelling behavior.

On-demand inactivation

Materials & Environment 02/01/2021

An antimicrobial hydrogel is to be developed.

Communication of characteristic values describing the metallic appearance of prints

Offset printing 10/31/2020

Objective parameters are to be established that correlate with the visual impression of printed metal surfaces.

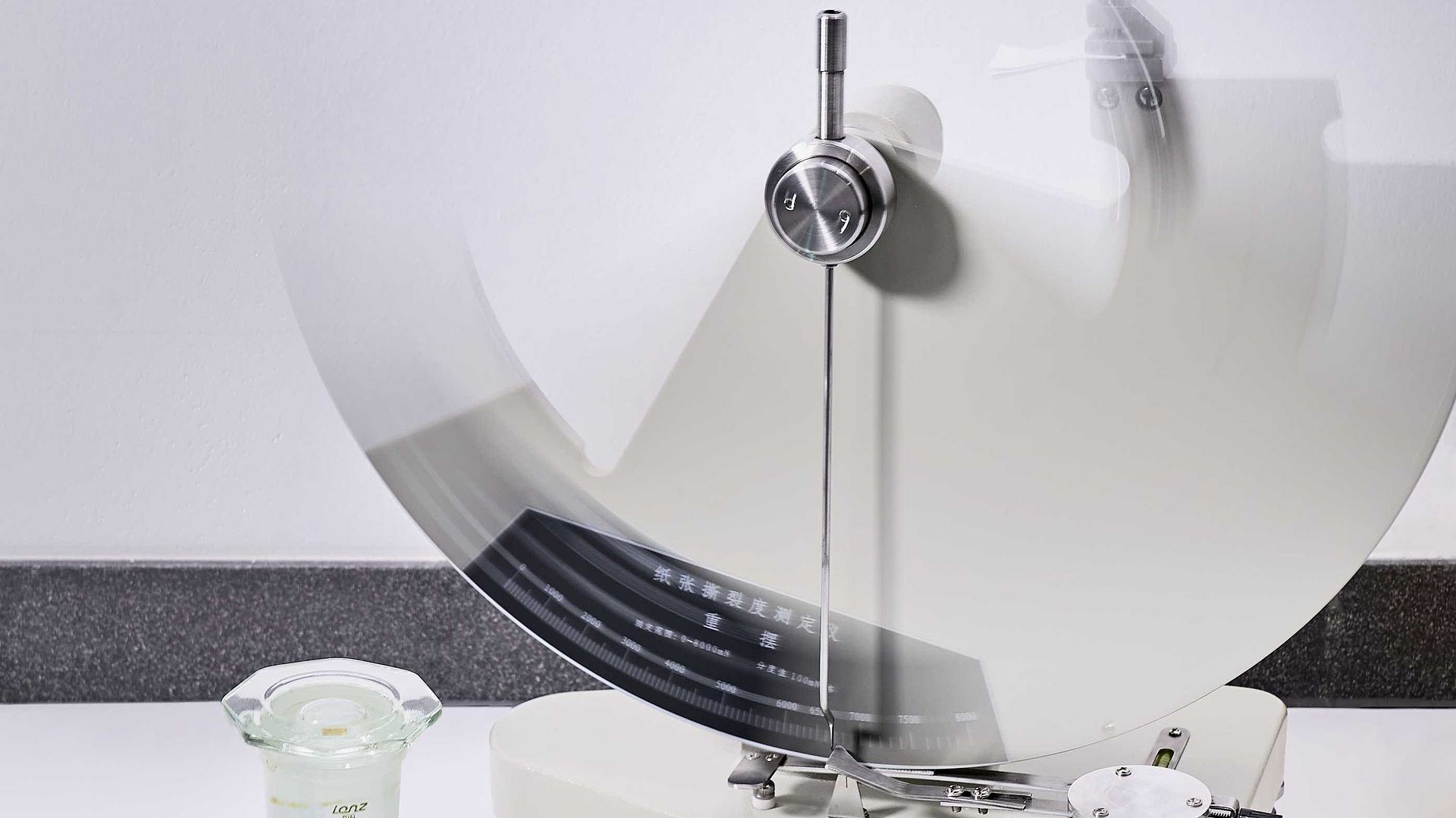

Laboratory method for the practical and reproducible determination of the residual strength of papers for heatset web offset printing

Offset printing 03/31/2020

Within the scope of the research project, an already existing laboratory method for testing the residual strength is to be further developed.

Development of a printable primer system for direct glass printing

Materials & Environment 11/01/2018

The adhesion of UV-curable inkjet prints on glass bottles has not yet been satisfactorily solved. This is the point research starts.

Modelling the printing behaviour in sheet-fed offset printing on the basis of measurable paper properties

Offset printing 04/30/2018

The paper-side factors influencing solid tone colouring and tone value increases in sheet-fed offset are to be determined.

Reduction of "Picture Framing" in sheet-fed offset printing through targeted selection of material and application parameters

Offset printing 03/31/2018

Within the framework of the research project, a better understanding of the development mechanisms of "Picture Framing" is to be achieved.

Test system for the evaluation of wettability and surface purity

Materials & Environment 01/01/2018

Test inks to deterimine the wetability of surfaces (polar / dispers) as well as application and evaluation units habe been developed.

Revision of the test standard for assessing the corrosiveness of damping solutions for offset printing

Materials & Environment 05/01/2017

Is it possible to perform the current corrosion test on fountain concentrates less time consuming and cheaper?

Regardless of whether you want to have a material tested by us or have a damage case assessed by Fogra, we will be happy to help you. The easiest way is to contact us by telephone with your request and we will discuss the procedure together.

It can also be advantageous, particularly in the case of damage investigations, if you first send us some samples for a non-binding and rough examination.

You can have a wide range of tests carried out on your consumables and printed products as well as investigations into the curing of UV prints. We find causes and solutions for problems that have occurred. In addition to quality assurance tests, Fogra offers assistance at any time in the event of damage.

![Fogra approval of washing agents [Translate to EN:] Fogra Waschmittelfreigabe](/fileadmin/_processed_/2/3/csm_fogra-washing-agent_8f4f025a62.jpg)