Topic of your interest

Top of the range equipment

Questions about a very wide range of materials or production results can be investigated using an array of state-of the-art equipment.

A large number of modern colour measuring devices make it possible to deal with all the issues involved in quality control of print products. In addition, complex phenomena of printing practice can be simulated using the institute's own sheetfed offset printing press and various test printing devices.

Determining sources of error and the reasons why a printed product might fail to satisfy the specified quality requirements requires the right analytical methods and the accumulated expertise of those operating the devices, who can draw on the collective experience of a body of 33,000 expert opinions. Whether a sample is volatile, aqueous or solid, Fogra is able to determine the components and composition unambiguously and precisely.

As a general rule, if there is no commercially available device for a task then Fogra will design and build one itself.

We also stand for accredited quality management as Fogra’s security applications department operates the world’s only testing laboratory that is accredited for the full range of identity card and document tests.

Top of the range equipment

Thanks to funding from the Bavarian State Ministry of Economic Affairs, Regional Development and Energy, new equipment was purchased for the Printing Technology, Materials & Environment and Safety Applications departments:

- Spectrophotometer with an integrating sphere

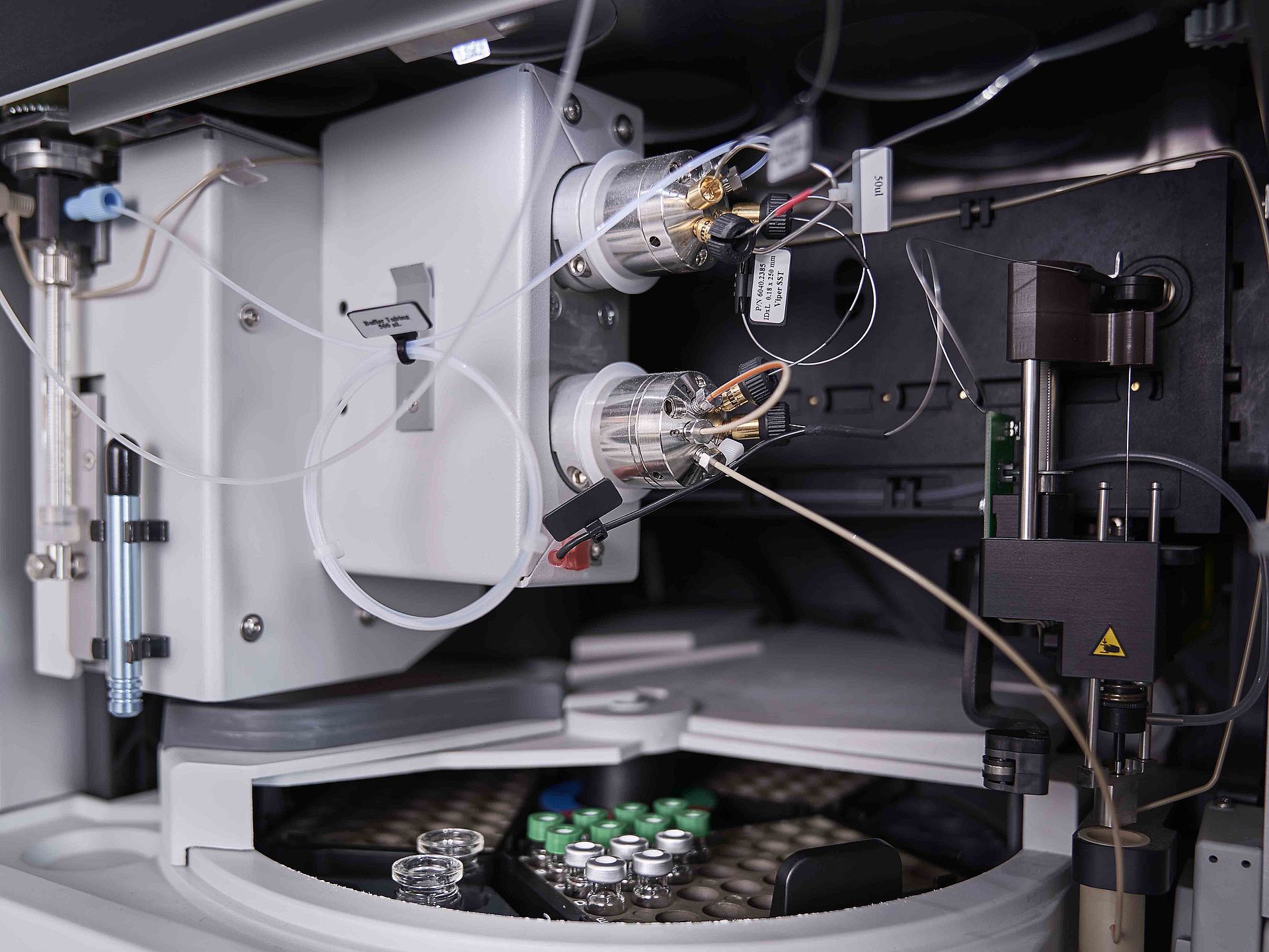

- Gas chromatograph with mass spectrometer

- Extensive test bench for Near Field Communication (NFC) consisting of a control unit, an amplifier, an oscilloscope and the necessary test coils

They are strategically important to Fogra for the further development of its technical capabilities. The benevolent support of the Innovation, Research, Technology, Digitisation Department under the leadership of Ministerialdirigent Dr Manfred Wolter made this grant possible.

A selection of

Fogra’s laboratory equipment

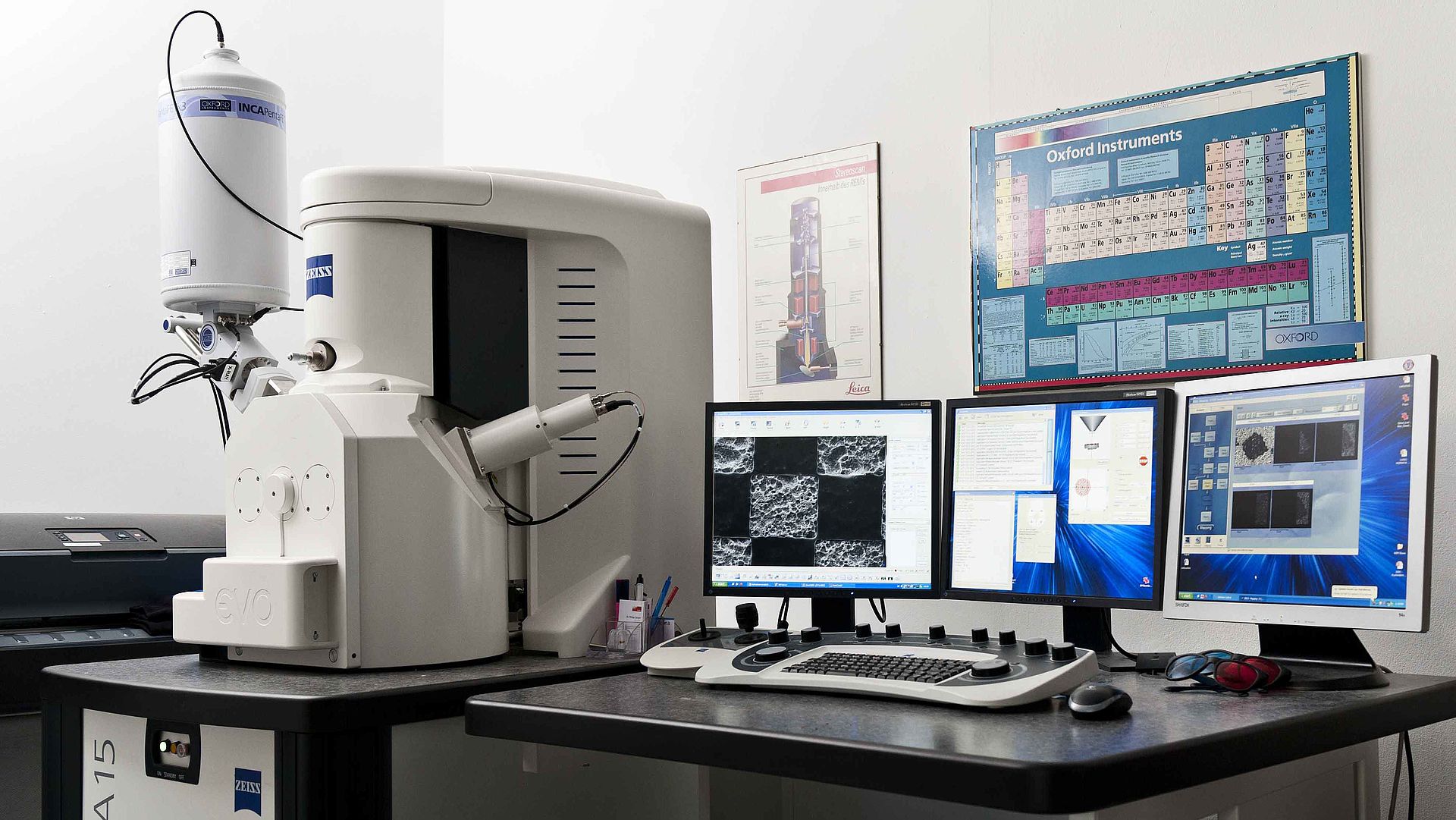

Scanning electron microscope

The scanning electron microscope (SEM) allows surfaces and cross sections to be examined under high magnification. An ion beam preparation device allows extremely smooth and precise cross sections to be prepared for analysis. This, combined with energy dispersive X-ray spectroscopy (EDX) allows the distribution of elements to be measured and visualized qualitatively and quantitatively.

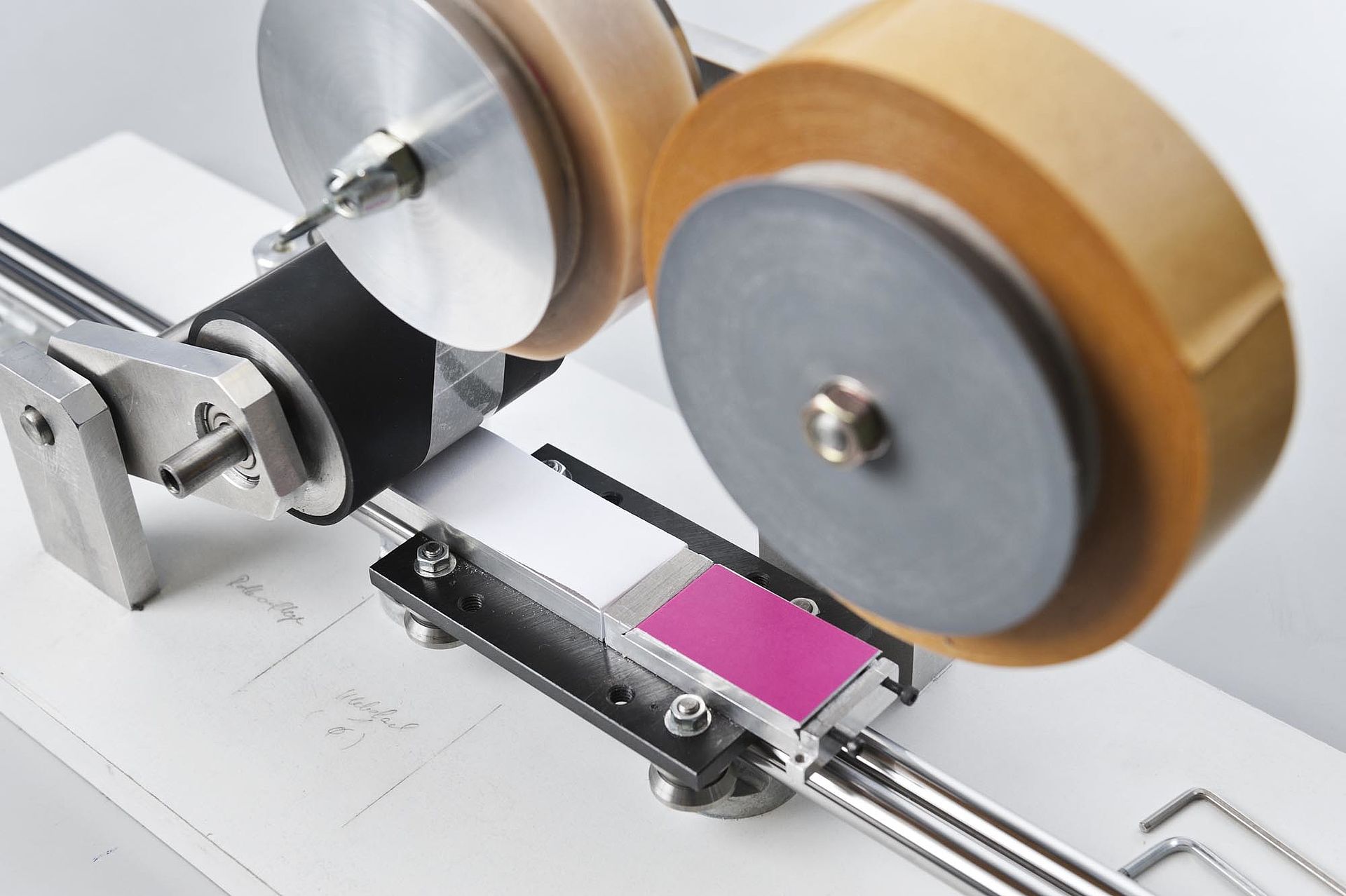

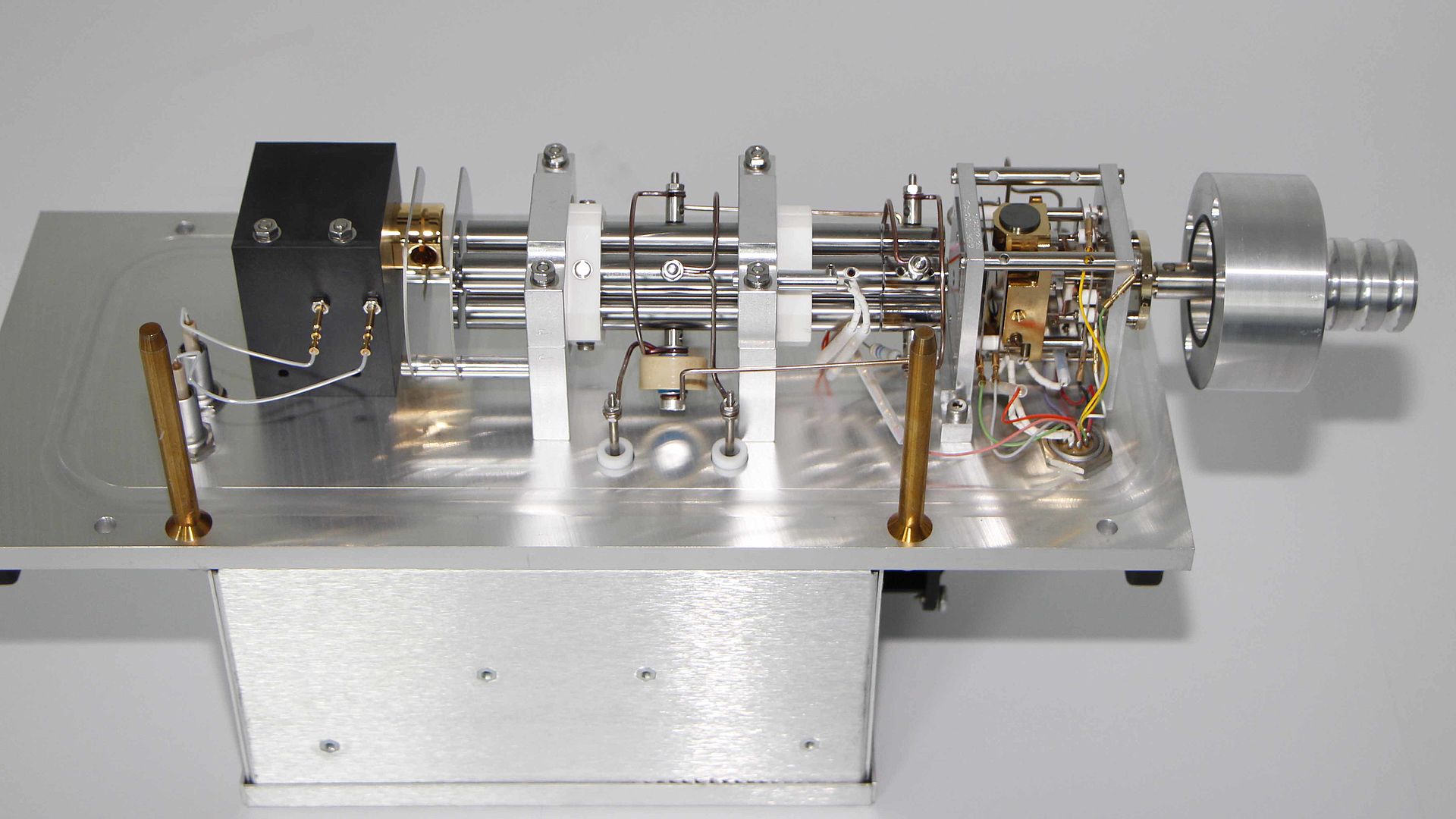

Modular inkjet test bench

UV inks and coatings may be printed and then cured with an LED or mercury vapour lamp source. On top of this, various different inkjet labelling print heads can be used in combination with the corresponding types ink. The modular structure of this test bench gives us a great deal of flexibility to simulate various printing conditions.

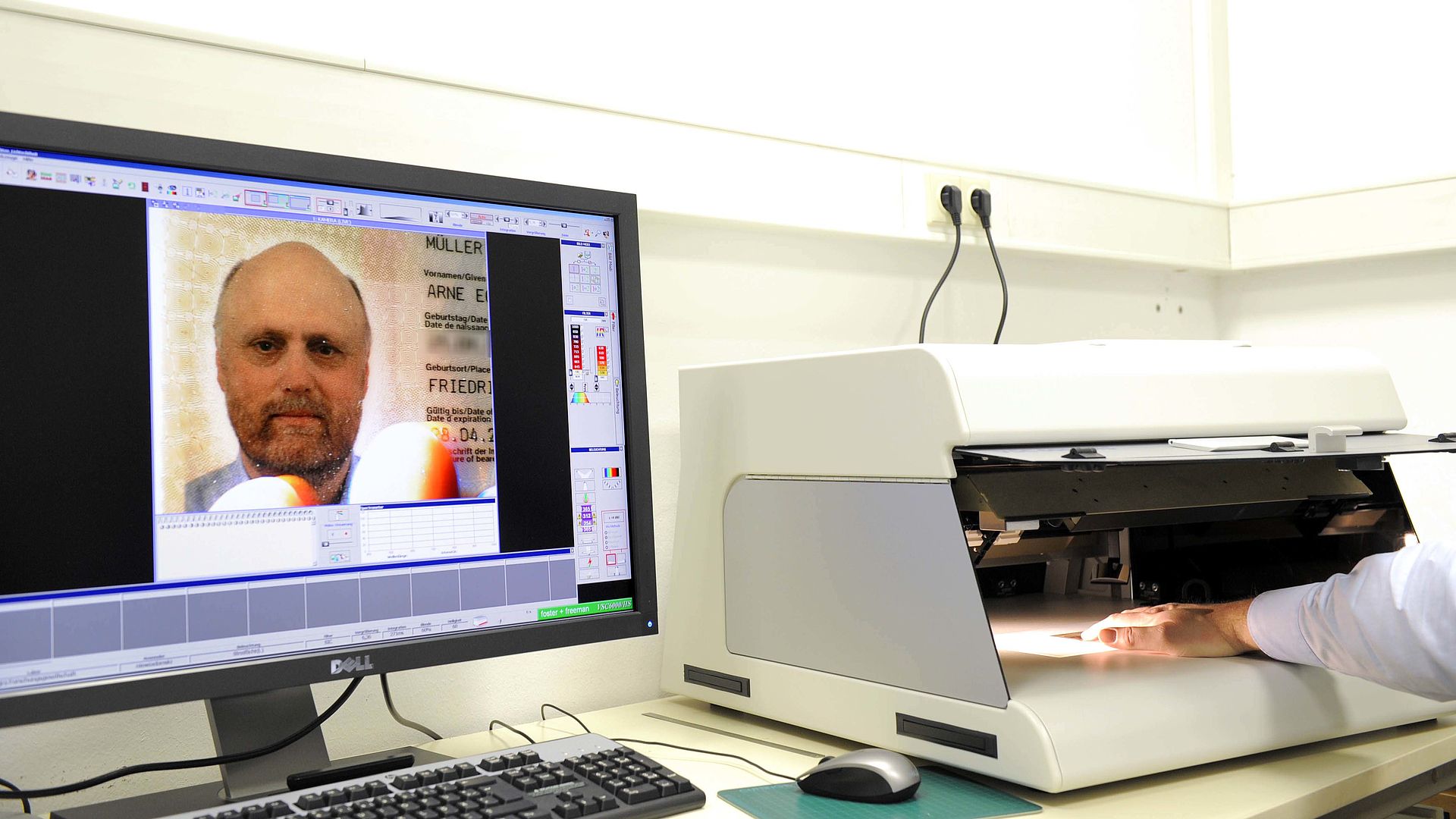

Document analyser

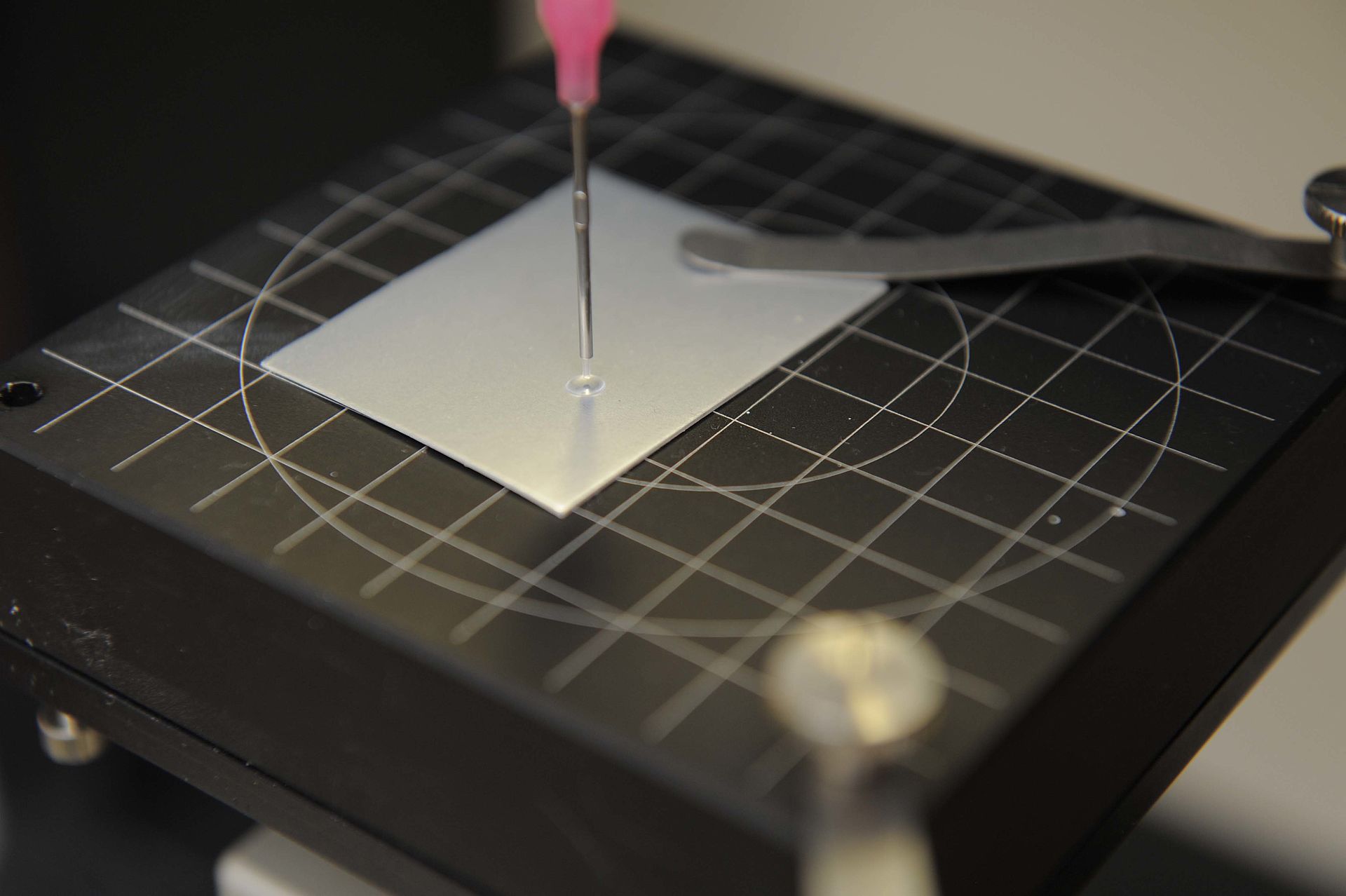

This multispectral workstation analyses documents and their features, whether visible to the human eye or not. Examples of the nearly unlimited potential uses for this device include real time analysis, precise documentation of changes resulting from natural and artificial ageing and area absorption spectra.

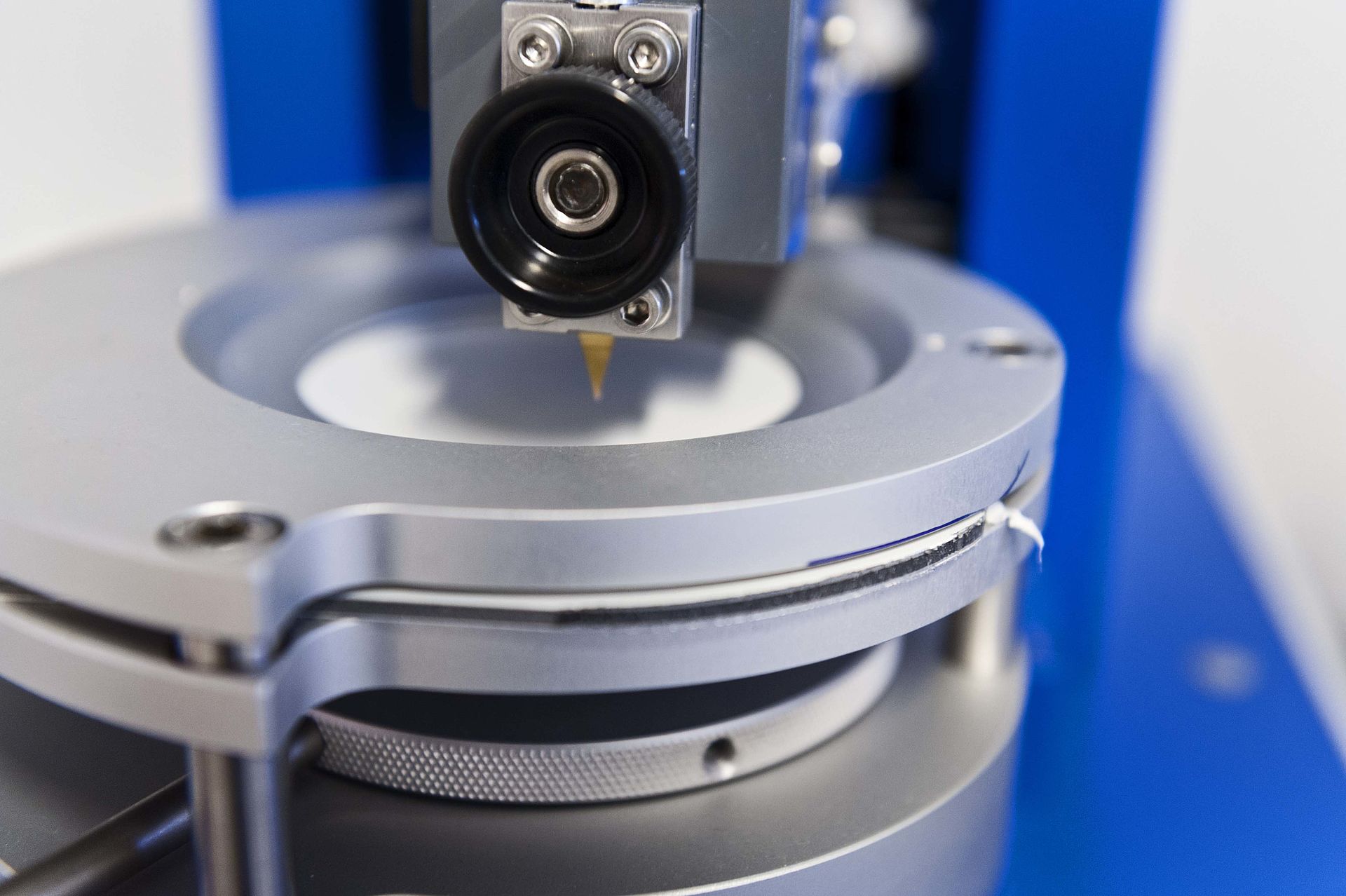

3D microscope

Penetrating insights and differing viewpoints are what are needed for innovative ideas, ground-breaking research and fault analysis; and this microscope, which operates at the interface between microscopy, surface and 3D measurement technology, feeds us the necessary new live information within seconds. Building up the third dimension layer by layer.

Spectroradiometer

“Measuring as we see” becomes a possibility with the spectroradiometer because any viewing scenario can be flexibly simulated using remote measurement. So, for example, an advertising banner might be scanned from the opposite stand in a football stadium in order to check whether the fans see the desired brand colour.