Topic of your interest

Researching Materials & Environment

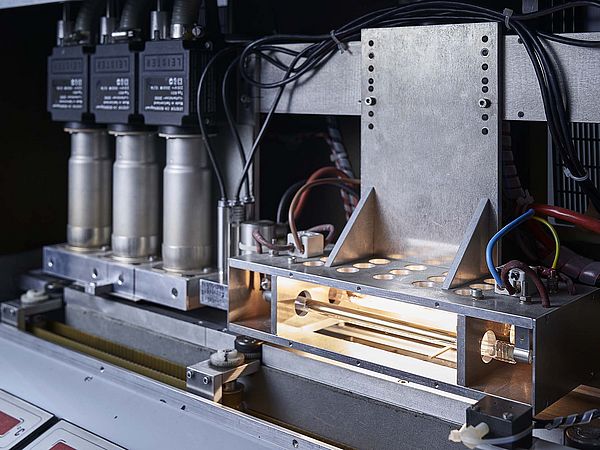

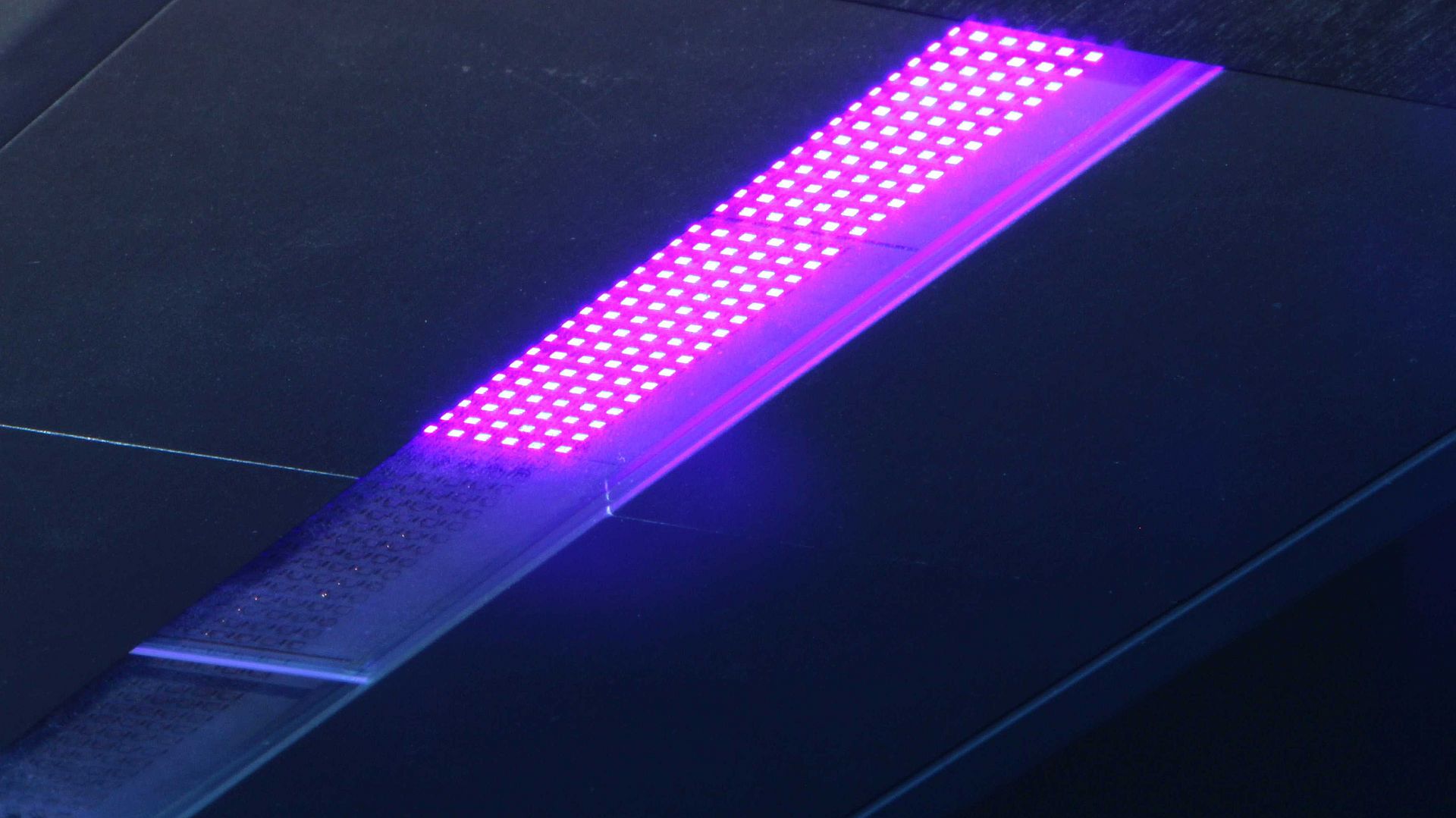

The research area covers the properties of individual materials (e.g. printing inks, substrates) and their behaviour in the printing process (e.g. curing, change of properties due to the printing process) as well as the interaction of individual components (e.g. adhesion, emulsion formation). Furthermore, environmental compatibility and energy optimisation are important topics.

Focus areas

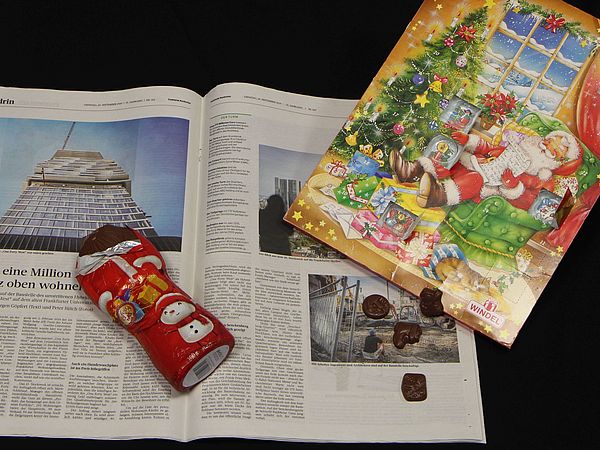

Mineral oil

Since the publication of the suspected mineral oil contamination of chocolate from Advent calendars 2012 in Germany, the topic has become a focal point in the german printing industry and thus also in Fogra's research activities. UBA report (German version with English summary) available free of charge.

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/1/csm_fogra-heatset_8f991b0f76.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/3/csm_fogra-papierstapel_ca2398c293.jpg)