Topic of your interest

The visual quality assessment of products is of great importance in various industries and has a significant influence on the success of companies. Among other things, color changes play a central role here. A gray scale is often used to evaluate these. However, this has certain disadvantages: On the one hand, two people are required for this type of assessment, which can lead to divergent assessments.

Secondly, the gray scale only offers a limited number of gray levels, which means that finer deviations in specific color spaces, such as pastel shades, cannot be accurately recorded. This is where the present research project comes in. An analysis method is being developed with which color deviations of printed plastics can be determined.

Solution steps

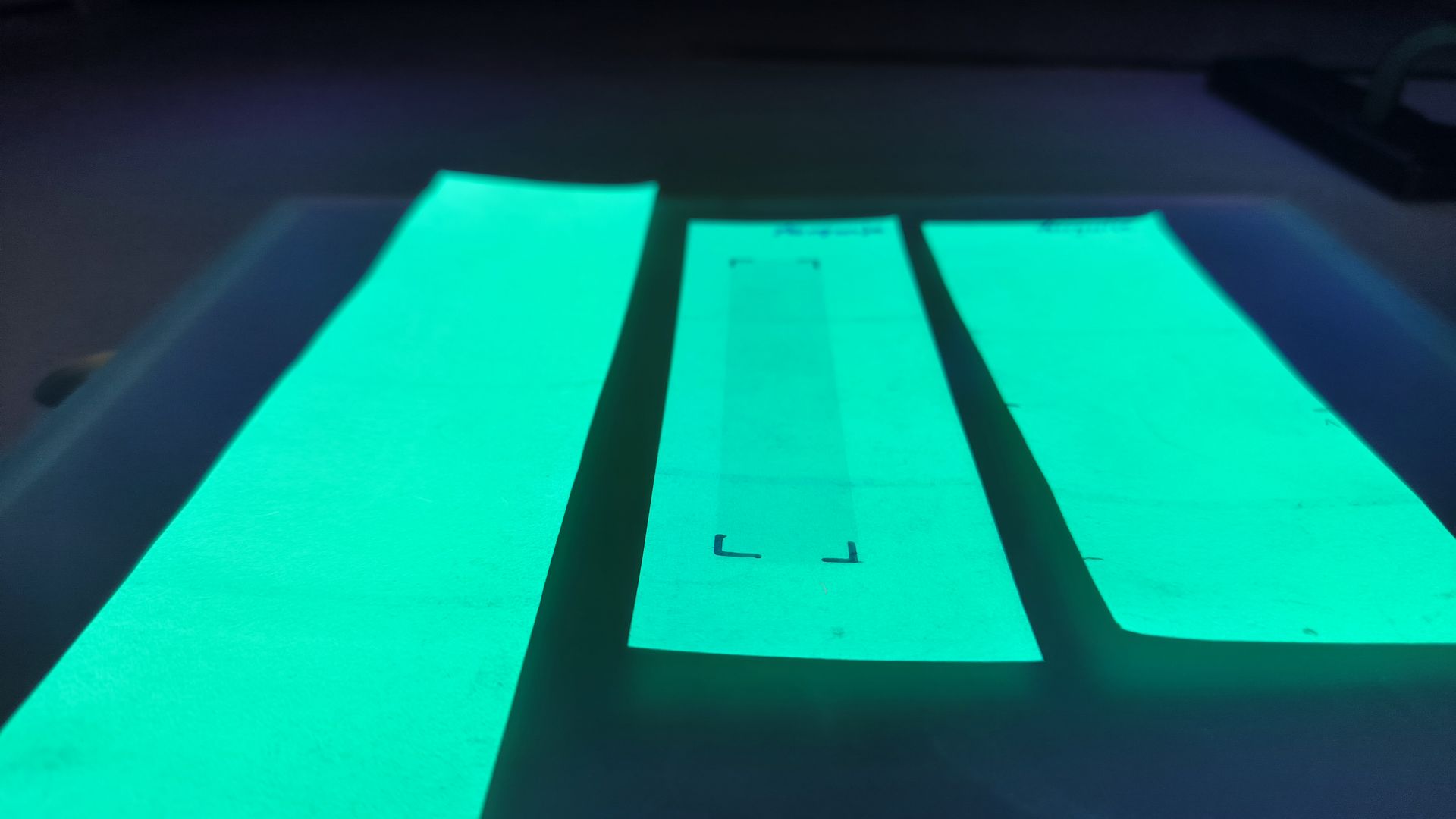

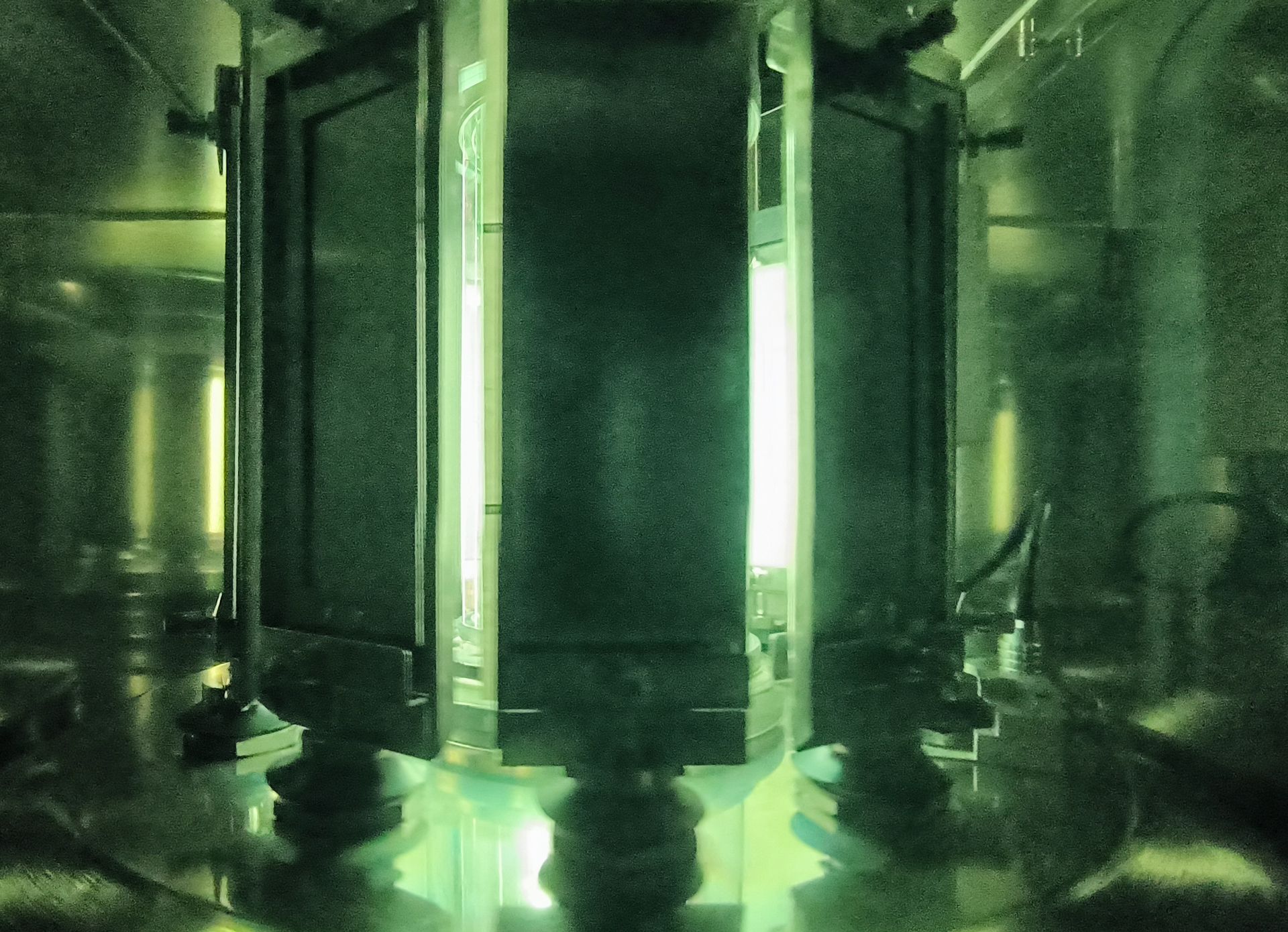

In the first step, a measurement method is developed with which high-resolution images of a print image and a specified reference can be created. An algorithm is then programmed in which the so-called PSNR-HVS-M metric (Peak Signal to Noise Ratio - Human Visual System - Modification) is implemented. It uses the peak value of the signal-to-noise ratio, taking into account the contrast sensitivity function and the intermediate coefficient masking of the DCT basis functions (Discrete Cosine Transform = DCT). This metric thus imitates the characteristics of the human visual system, such as contrast perception. With this approach, it is possible to develop an analysis method that comes very close to human visual perception.

Targeted results

The measurement setup and algorithm to be developed should make it possible to reliably and reproducibly determine the differences in quality between a printed image and a specified reference. Not only contrast, but also other important attributes such as contour, structure, color, sharpness, etc. are to be taken into account.