Topic of your interest

Therefore, within one paper category, printing is usually done with the same settings, although the solid tone colouration and tone value increases achieved can differ significantly. If corresponding changes occur with a new paper, the desired colour appearance of the print product will be missed even with identical paper colour.

Solution steps

In order to reduce the time required to set up the inkjet machine and at the same time ensure colour reliable print production, the research project aims to establish suitable paper parameters. For this purpose, a large variety of paper is to be printed with different highspeed inkjet machines. The print results will be compared to extensive laboratory tests and examined for correlations.

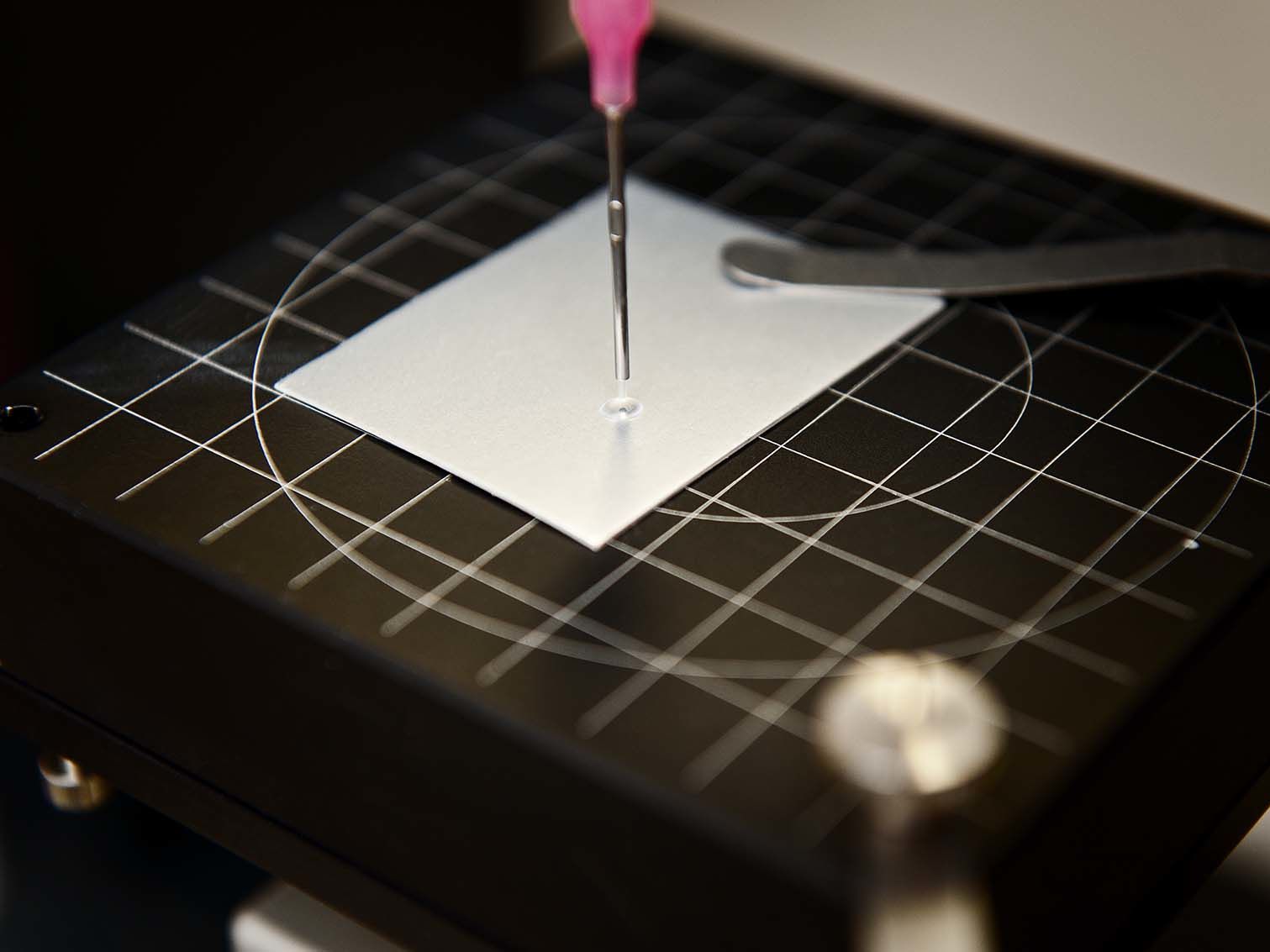

In addition to the standard paper characteristics, the paper tests to be performed include numerous additional properties. These include drying time, local colour fluctuations, surface geometry, spreading, penetration and lateral light scattering.

Achieved results

The correlations determined are different for all the presses examined. In addition to the presence or absence of a coating, the most relevant paper properties were gloss, print-surf roughness, roughness values, light scattering and light absorption coefficients, oil absorption, contact angle parameters along the grain direction and specific pore volume.

These variables alone often allow a rough prediction of the printing result. An improvement of the correlations can additionally be achieved by including the thickness, the grammage, the specific volume or the sheet density, the ash content, the water absorption, the absolute water content as well as the contact angle parameters perpendicular to the grain direction.