Topic of your interest

The aim of the research project is the development of a printable primer for UV direct printing on glass, in particular for application on reusable beverage bottles, which can be applied after the flame silicatisation used for adhesion. The pre-treatment of the glass, for example by flame silicatisation, and the formulation of the primer solution must be developed or coordinated in such a way that optimum adhesion to the substrate on the one hand and to commercially available UV-curing inks on the other hand can be guaranteed.

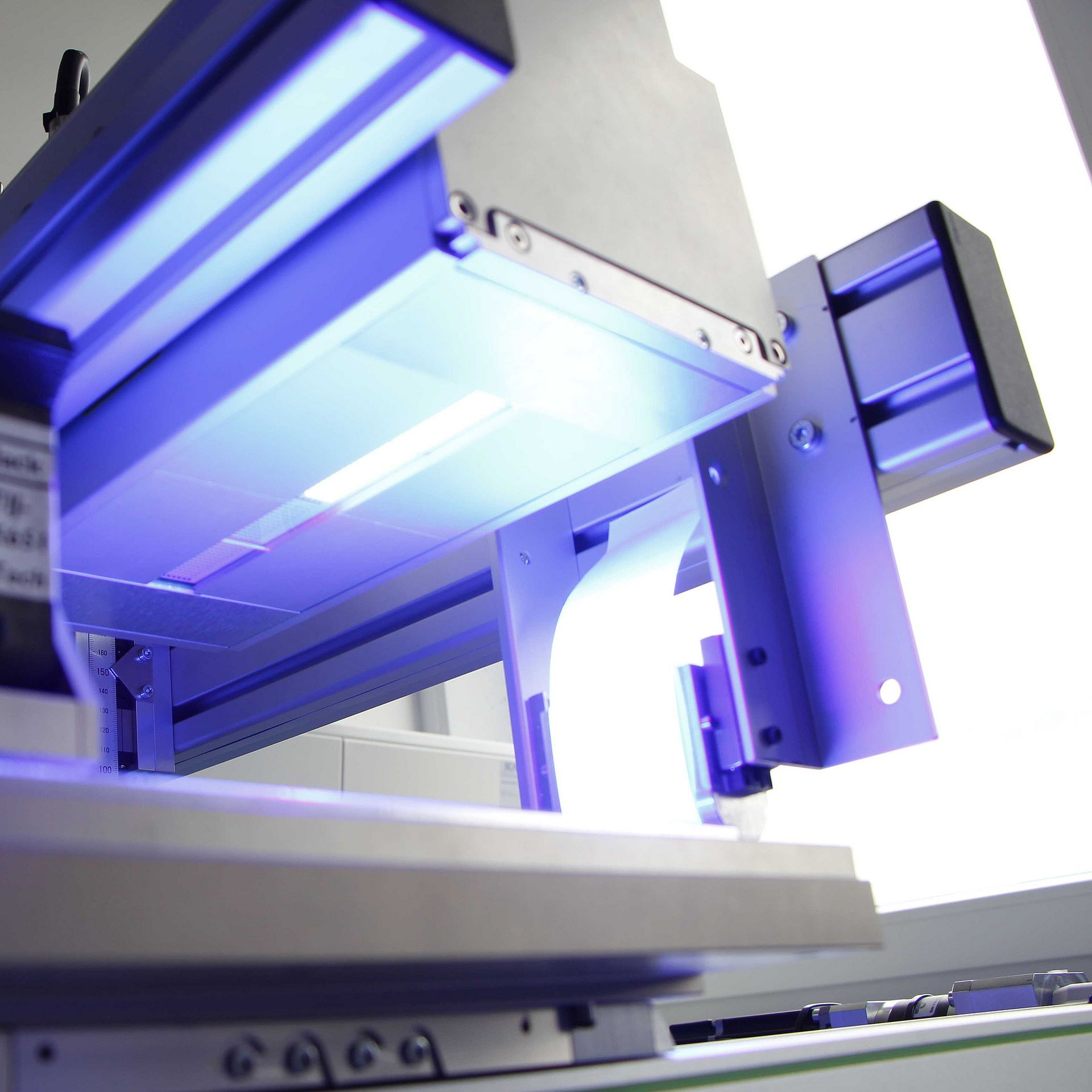

In addition to adhesion, it is also intended to ensure the durability of the print for subsequent processes (filling and reuse). In order to save running costs in subsequent production operations, it is planned to apply primer and ink wet-on-wet and cure them together using UV LED technology. With regard to bottle recycling, it is also intended to develop a method for removing the imprints. In the course of a successful implementation of the project, UV direct printing should become significantly more attractive for applications in the field of glass printing, especially hollow glass printing.

Solution steps

Several steps are necessary to achieve the goal of the research project:

Determining the compatibility of print heads with possible primer components

Development of suitable primer formulations that theoretically meet the necessary requirements

Printing tests with the primers to ensure reproducible and homogeneous printability

Development of a suitable test procedure for determining liability

Comparison of the results of the new formulations with those of commercial primers

Development of a process for removing the printing in the bottle washing

Targeted results

In bottle printing, glass primers have so far generally been applied to the entire surface of the glass bottles using a spray process. In this project, research is being conducted into how inkjet print heads can be used to apply the primer.

One challenge is to apply homogeneous and very thin (< 100 nm) layers of the primer. The formulation required for this is not the same as for conventional UV-curing inks and therefore represents a major challenge for printing. Optimisation tests on printability are currently being conducted as part of the project. It is now possible to produce homogeneous layers at a speed of approx. 40 m/min.

In the institute of our cooperation partner, tests are already being carried out to determine the adhesion of colour films with different pre-treatments of the glass surface before priming. In addition to the cross-cut used in the printing industry, pressure shear tests and stamp break tests are also carried out.