Topic of your interest

When using commercially available test inks to evaluate the surface energy or wettability of surfaces, the result obtained is highly dependent on the test ink set used. Furthermore, there is no comparability with the results of contact angle measurements. Therefore, the research project aims to develop an ink system consisting of a polar and a disperse ink set as well as a master ink for the general differentiation of surface qualities.

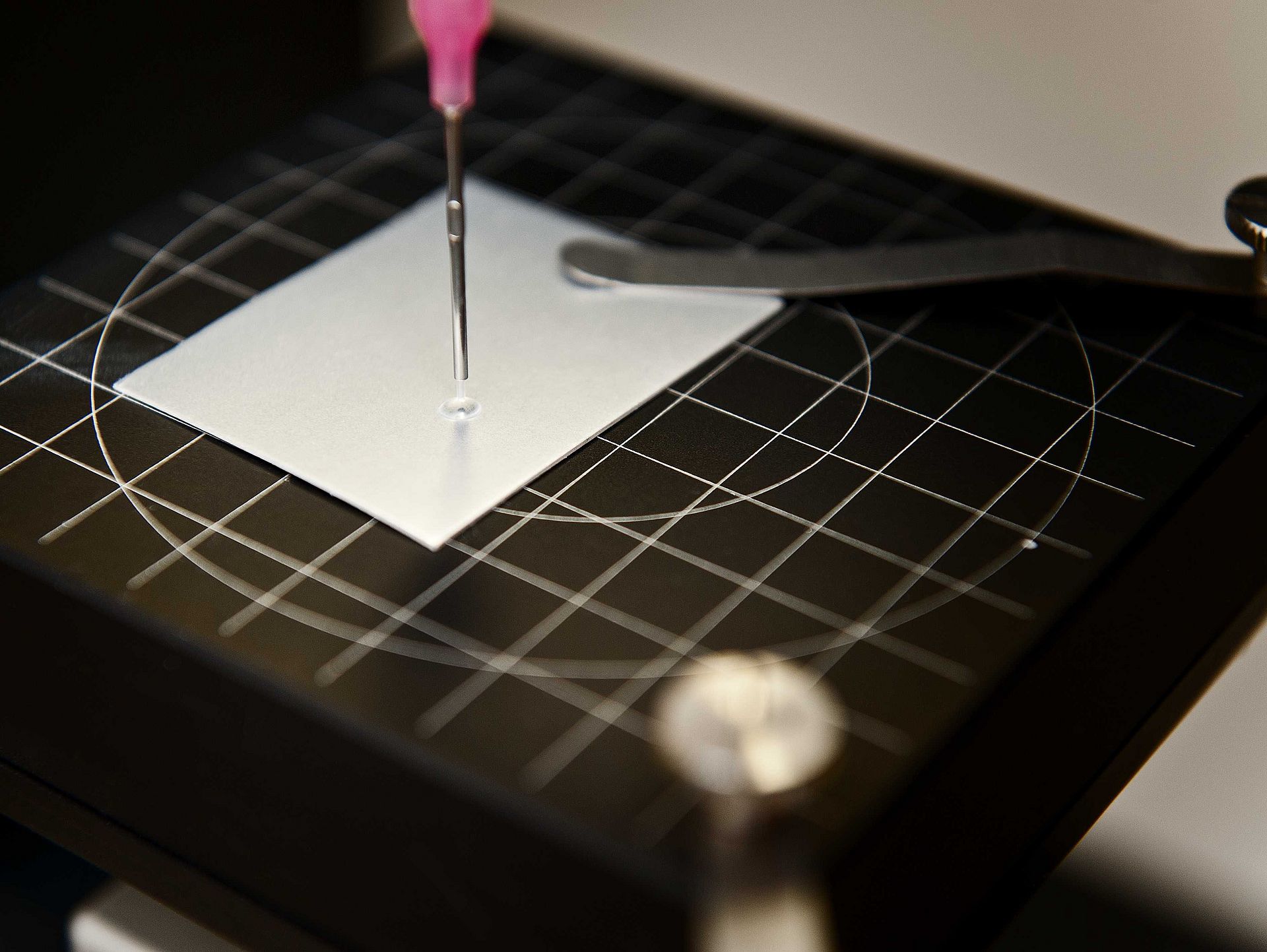

Furthermore, both an automated application procedure and a software-supported evaluation application are to be developed in order to obtain a reproducible result independent of the user. Such a procedure can contribute, for example, to reliably test aged films, to continue using them if necessary and to avoid waste.

Solution steps

Several steps are necessary to achieve the goal of the research project:

- Creation of a test panel of substrates to determine the surface tension and thus verify the new test inks

- Development of a standardised application method for ink application

- Development of the evaluation procedure (App)

- Development of new test intensities for predominantly polar or disperse surfaces

- Formulation of a “master ink” to determine the surface texture (more polar or disperse)

- Practical suitability of the new inks with the surfaces from the test panel