Topic of your interest

Solution steps

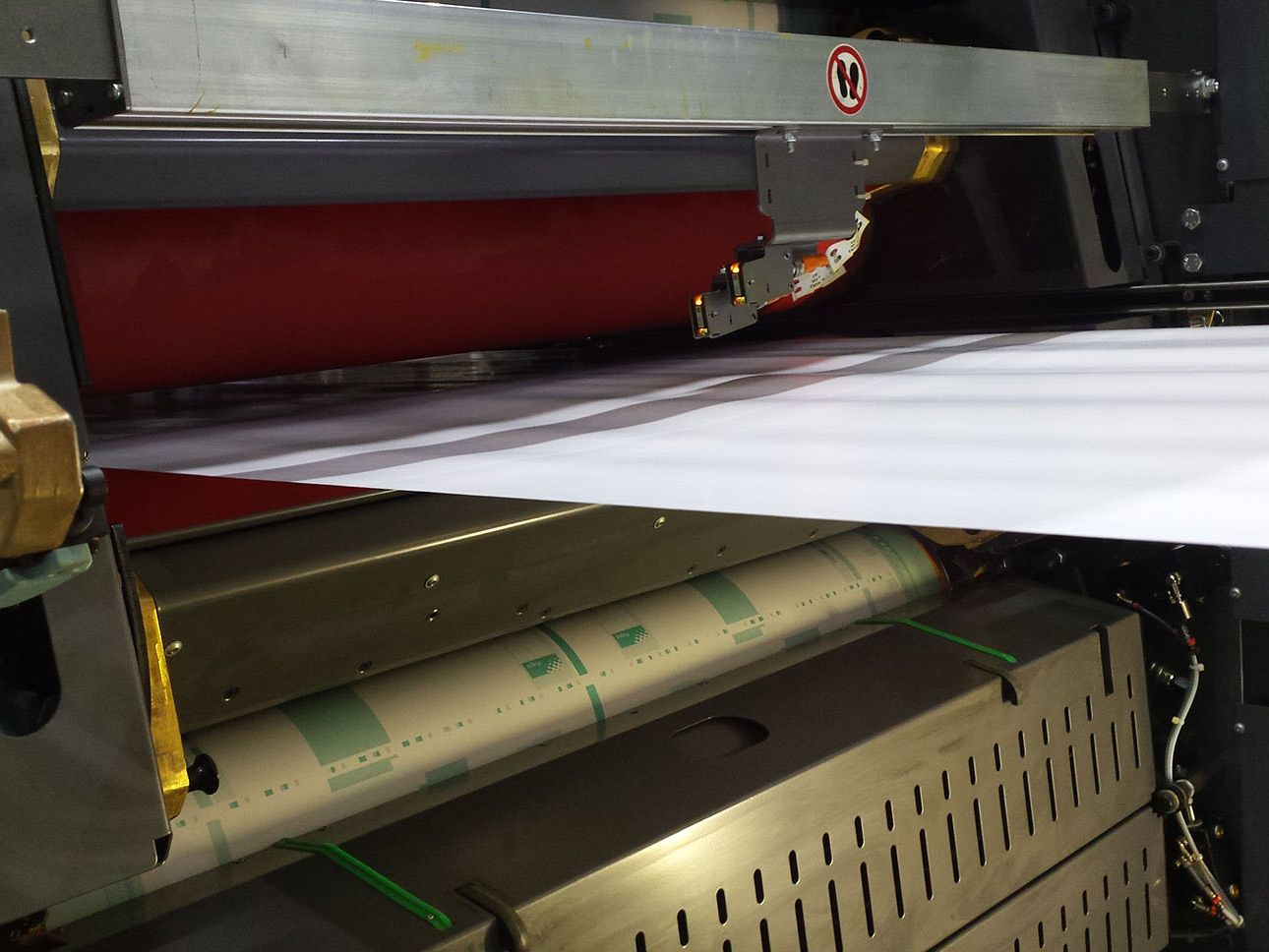

A cost and CO2 calculator is to be developed, taking into account the usual work processes, which will enable a well-founded comparison between production operation with heatset dryers and with LED UV lamps. The data required for this is to be determined in the course of extensive research. In addition, papers are to be examined with regard to their suitability for the "coldweb" process, both on a practical printing press and in the laboratory.