Topic of your interest

Laboratory method for the practical and reproducible determination of the residual strength of papers for heatset web offset printing

Short name: Residual strengh of heatset web offset papers

Fogra no. 42.029

Project leader: J. Gemeinhardt

Funding: BMWK (IGF) via AiF

Timescale: 01.04.2018 - 31.03.2020

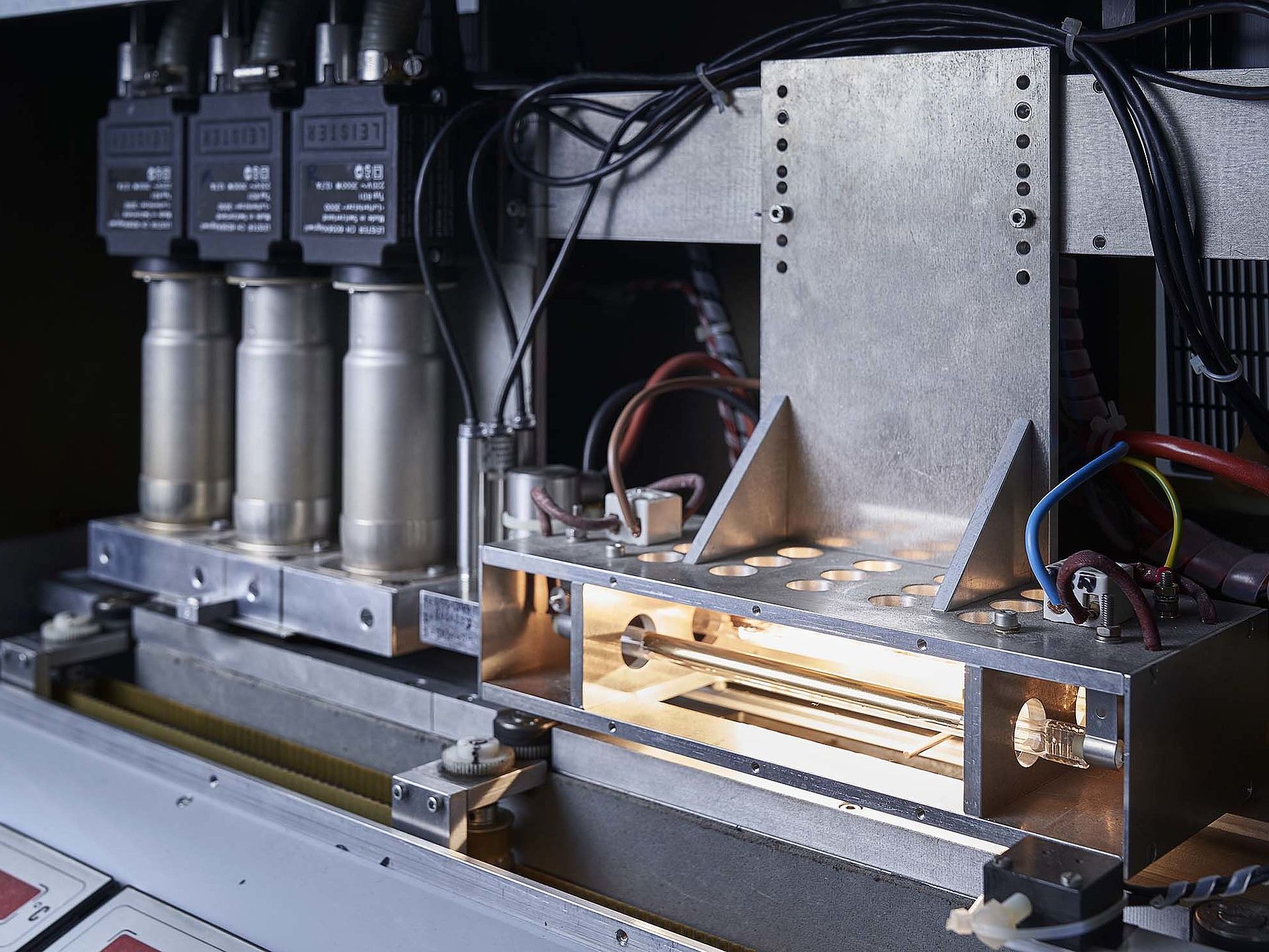

In heatset web offset the paper web first passes through the printing units before entering a heatset dryer in which the mineral oils from the inks are vaporised. At the same time a lot of water is removed from the paper and it becomes brittle. This, in combination with the mechanical stress during folding, leads to a substantial reduction in strength properties

If the residual strength is too low, the fold may break. Usually, the problem is noticed too late when individual pages of the finished print product are torn out of a stapling or thread stitch binding. In order to avoid this, the research project aims to further develop an existing laboratory method for testing residual strength.

Solution steps

First of all, the influences of the dryer, the selected settings and adjustments and the test procedure itself are to be investigated. The results are to lead to a detailed specification, which is to be verified by round robin tests in various paper laboratories.

The test method must be adapted by comparing the residual strengths of collected production samples with the corresponding results of the paper tests so that it reflects the average print production as accurately as possible. In conjunction with a qualitative assessment of the finished print products, the residual strengths determined should continue to be used to define suitable boundary values.

Achieved results

Round robin tests in various paper laboratories and repeat tests over a longer period of time suggest that sufficient measurement accuracy or reproducibility can be achieved when determining the residual strength. The prerequisite for this is strict adherence to the procedure defined in the research project.