Topic of your interest

Problems often occur during bookbinding processing of picture printing paper, which are based on the paper breaking in the fold. Concrete defects are particle deposits in the product and broken edges of the fold. The project has developed test methods for these defects that can be used to assess the coating strength in the fold as a specific paper property. This makes it possible to test an important paper property.

Solution steps

Initially, a large number of commercially available image printing papers will be characterized in terms of their mechanical properties using standardized paper tests. Various methods are being developed to measure the paper and coating particles released from the fold and the integrity of the fold edge, such as dust extraction and adhesive strip tests.

The developed methods are always related to image analytical tools. They are applied to the test papers and the results are correlated with the standardized paper tests.

The project also focuses on the influence of coating and creasing processes on line breaks in the fold. The aim is to analyse a possible correlation between coating content in the paper and coating strength.

Achieved results

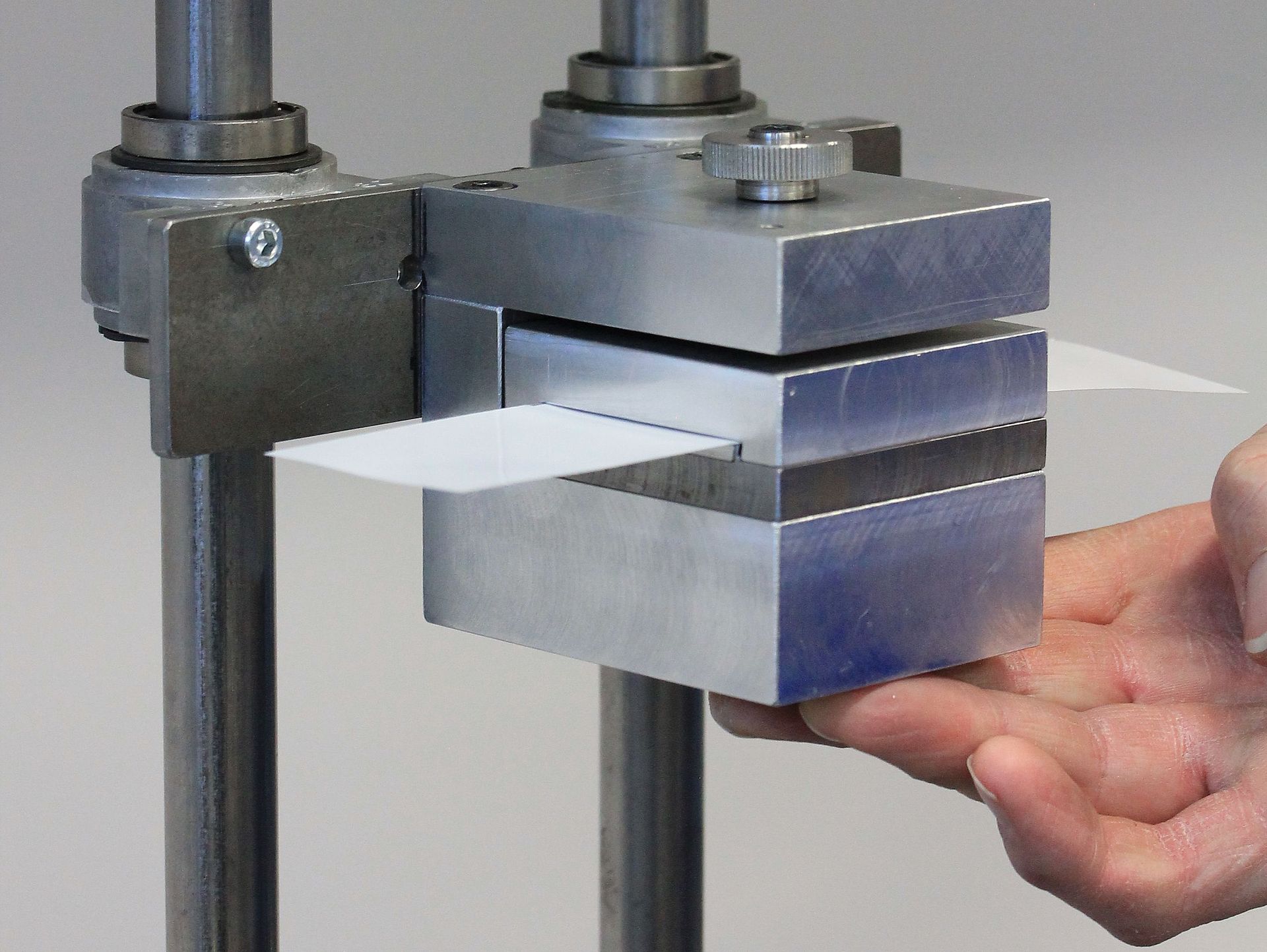

The inner fold test is used to assess the coating particle deposits on a paper after folding. The test involves folding an unprinted strip of paper and applying a force pulse in a testing device to transfer the coating particles from the inner fold of the paper to a carrier, which is then analysed by image analysis.

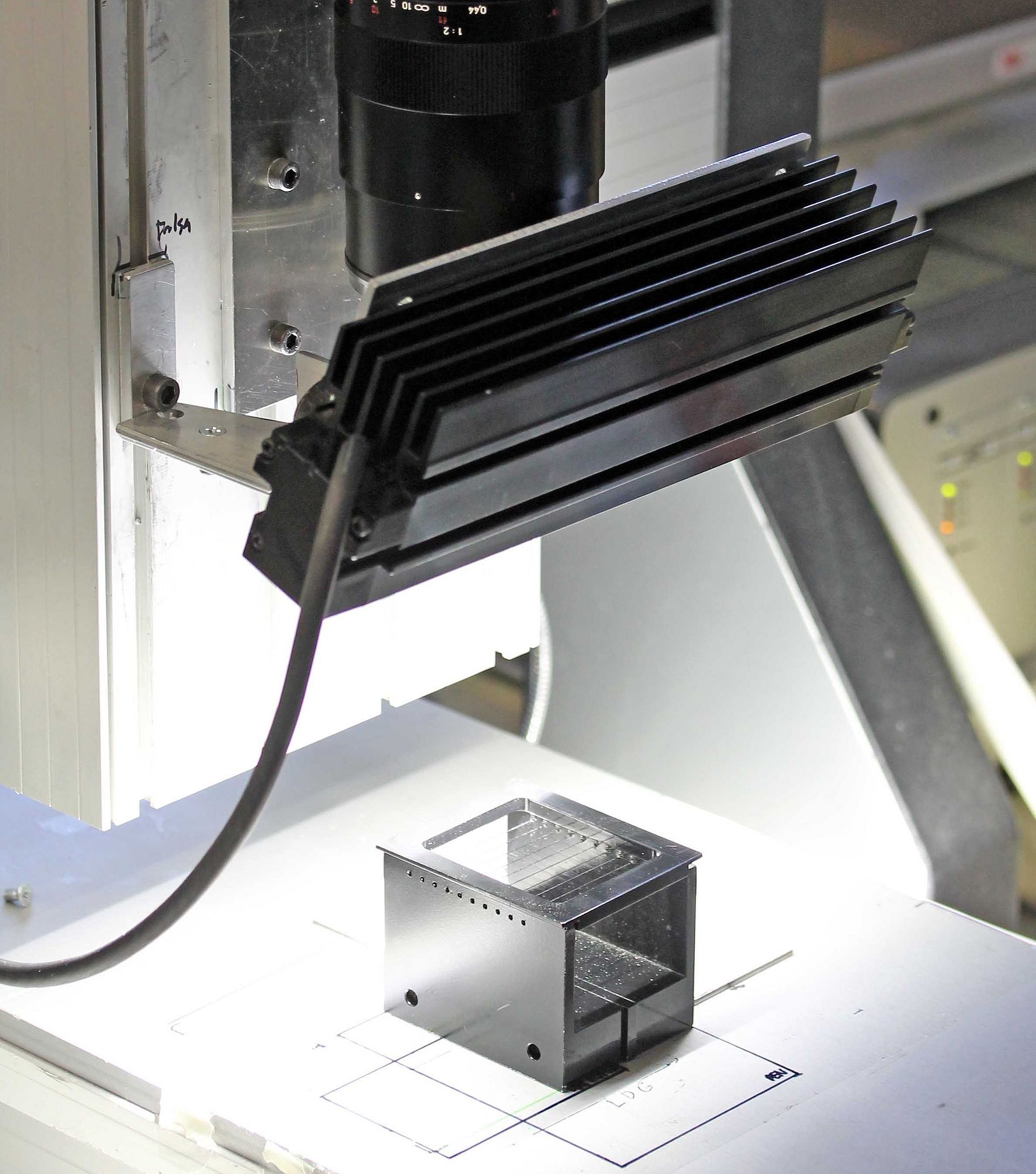

The outer fold is checked to ensure that the fold edge is undamaged. This involves printing and folding a strip of paper and analysing the edge of the fold with an image analysis. Algorithms were programmed for image analysis.

In extensive test series the papers were examined and the measurement uncertainties of the methods validated. The results showed significant differences between papers both in the standardized paper tests and in the newly developed test methods. As expected, s creasing generally had a positive effect on line breaks in the fold. There was no correlation between the coating proportion in the paper and the coating strength in the fold.

A draft standard for internal folding testing has been included in JWG 39 of ISO/TC 130.