Topic of your interest

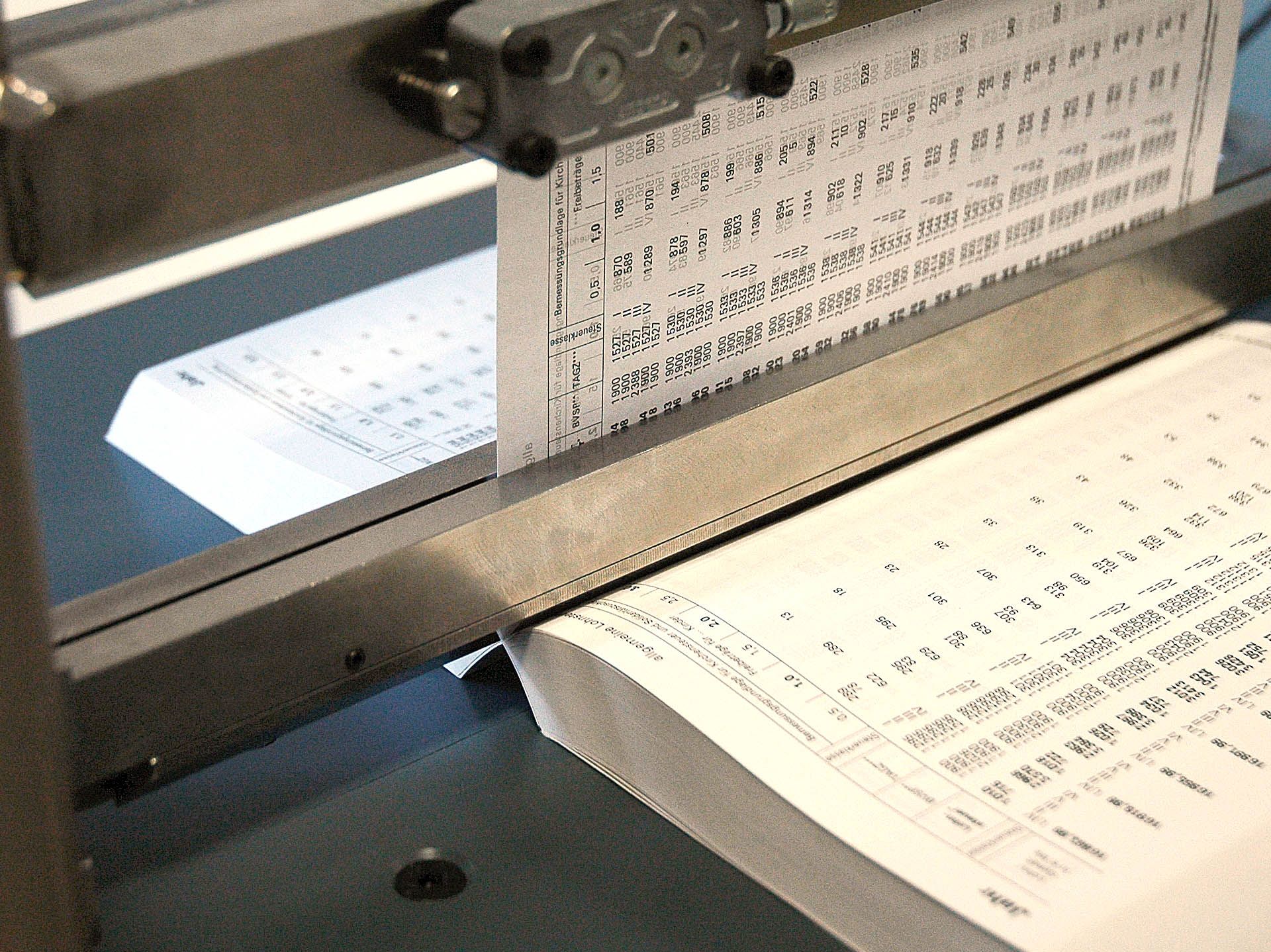

In this research project, the pull test procedure

The pull test is an established test method for assessing the quality of perfect bindings, which is very important, particularly for production control and the handling of complaints.

Solution steps

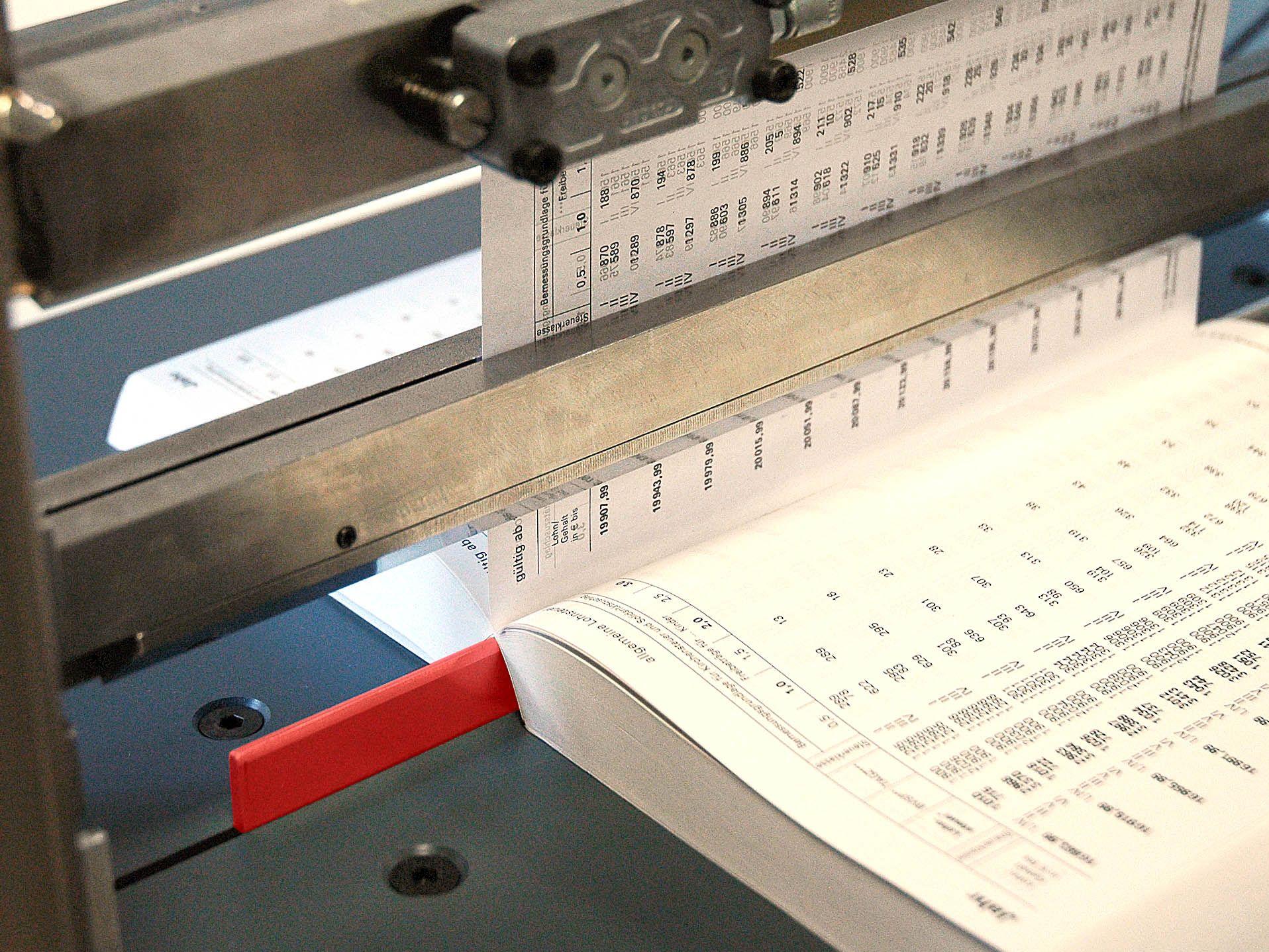

Based on a material testing system, a trial pull tester is first designed and built, which allows the targeted variation of the test sequence and various test parameters. The test sequence is automated as far as possible to minimise operator influence. Within the scope of an analysis of influencing variables, the specimen position, the opening angle, the hold-down force and the pull-off speed are examined.

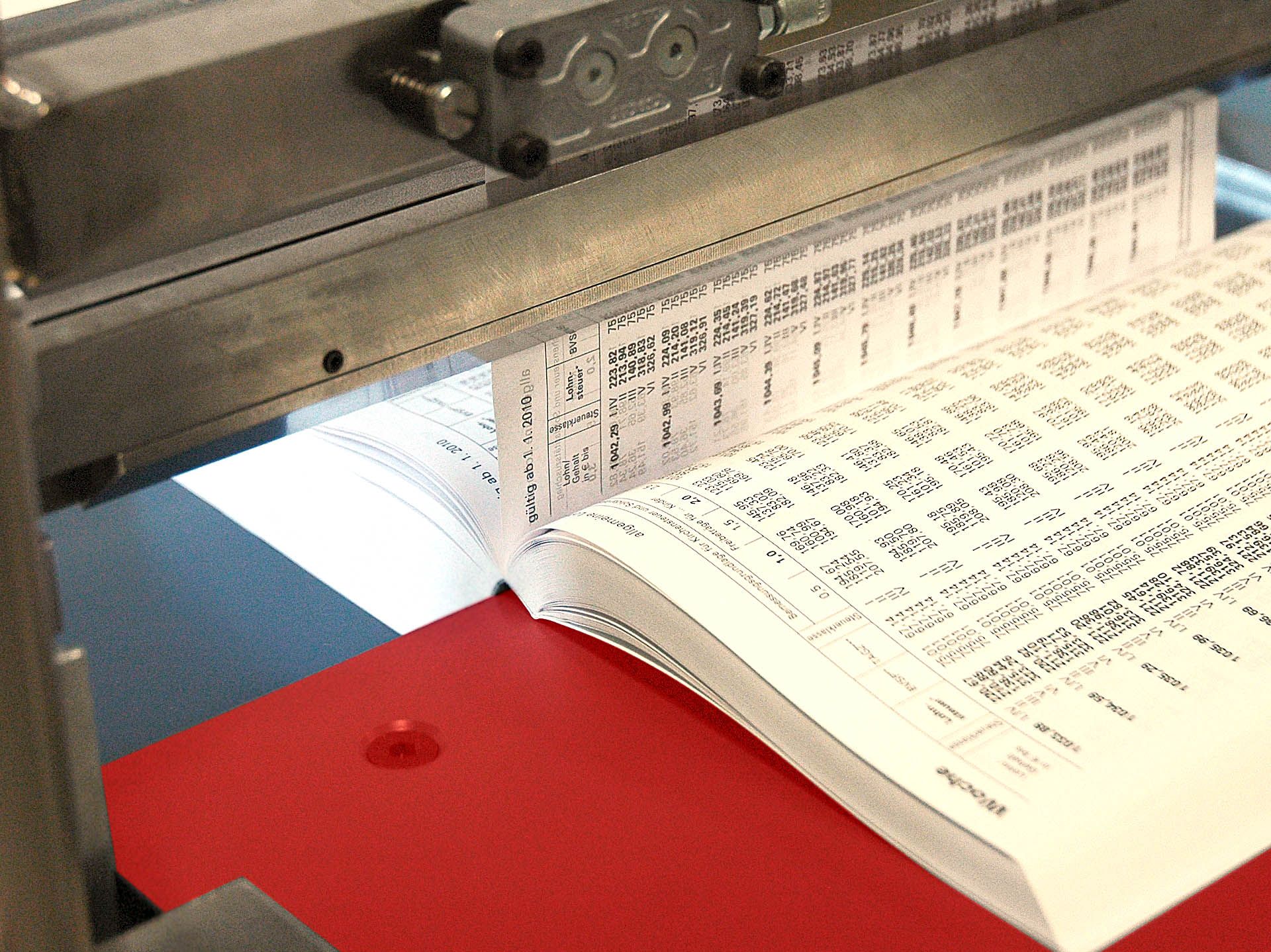

The adhesive-bound samples produced in a representative range are tested in pull test series. On the basis of the results, specifications for a test procedure capable of standardisation are finally specified with regard to execution and evaluation.

Achieved results

The influencing factors have different effects depending on the material and product properties. For example, it must be decided whether samples with a high clamping effect are already bent up strongly when held down or only during the tensile test, as this results in relevant differences in measured values. All decisions are made in favour of a low scatter of measured values and minimisation of invalid measurements (paper tear). For measurements which are carried out offset from the centre of the block, a step storage of the sample proves to be useful.

The recording of measurement curves allows an indirect determination of the impact behaviour by the pull test (gradient of the curve). Dynamic load tests as an alternative to the pull test have not brought any additional benefit.

The draft standard has been an ISO standard since 2017 (ISO 19594 “Printing technology - Test method for determining the sheet tear resistance of adhesive-bound products - Pull test with upward movement”).