Topic of your interest

Modelling colour appearance for full colour 3D printers

Short name: ColourMod 3D

Fogra no. 13.005

Project leader: Dr A. Kraushaar

Partner: Dr P. Urban (IGD Darmstadt), Dr A. Kienle (ILM)

Funding: BMWK (IGF) via AiF

Timescale: 1.10.2019 until 30.09.2021

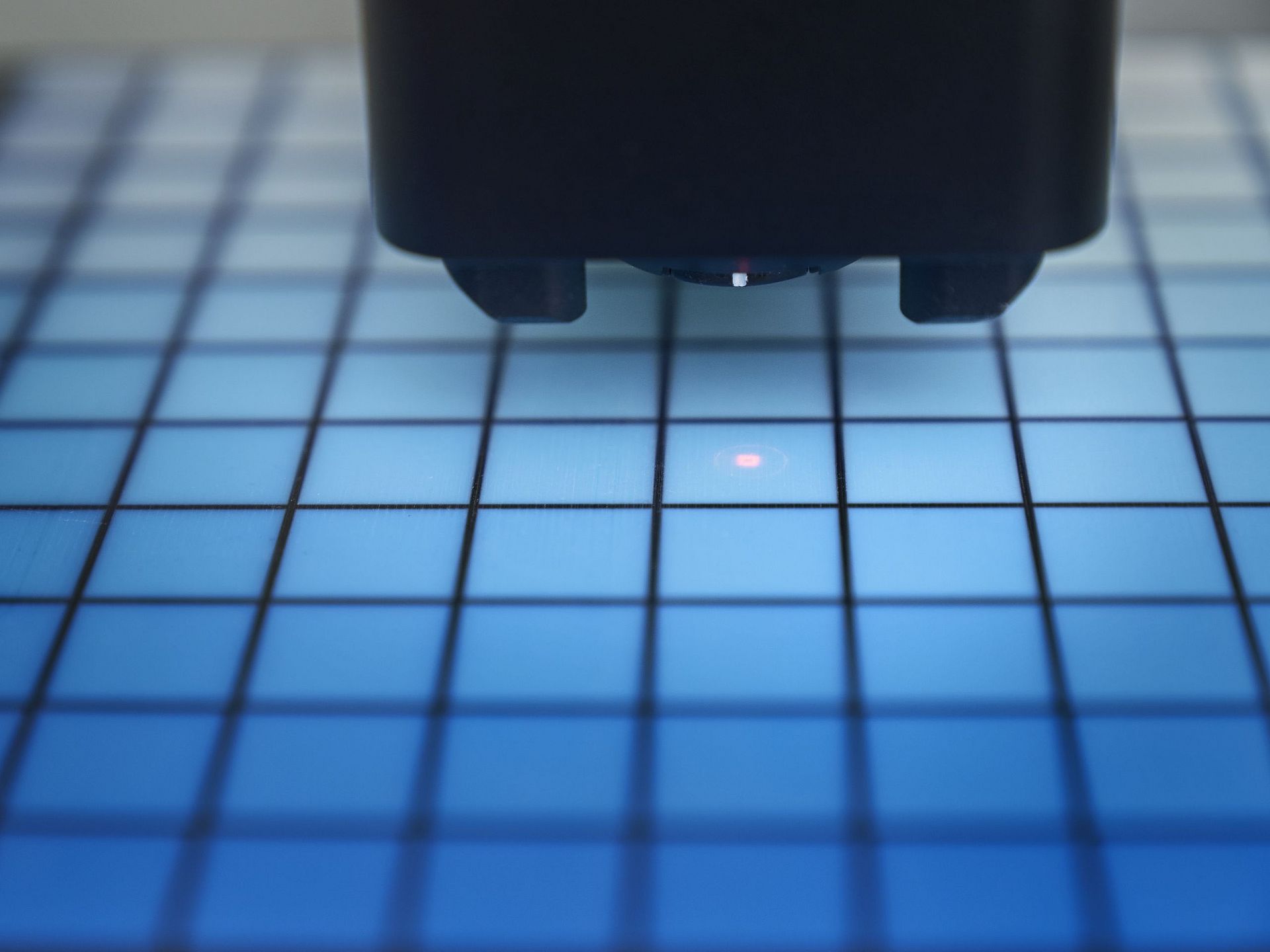

With the aim of reducing the temporal and monetary characterisation and profiling effort of modern 3D full-colour printers and at the same time ensuring a practice-ready colour accuracy, intrinsic optical parameters of full-colour prints are to be recorded in this project and modelled and validated for practice-relevant fields of application. The optical characterisation of the components produced in Polyjet and Multijet fusion will provide the necessary parameters for visual characterisation (colour and translucency) and thus enable profiling and control.

The implementation and performance optimisation of “Four-Flux-Model” as well as a feedback neural network promise a precise understanding of the relationship between the CMYKCW control values and the resulting colour appearance for many practical applications.

The 3D printing profiles to be developed are to be embedded in the ICC colour management architecture iccMAX (ISO 15076-2) and will be based on the control values available in practice for the concrete arrangement of the manufacturer or driver-dependent voxel arrangement.

Solution steps

First, the intrinsic optical parameters of full-colour prints are to be recorded and modelled and validated for practice-relevant fields of application. The implementation and performance optimisation of the “Four-Flux-Model” and the Monte-Carlo based training of a feedback neural network promise a sufficiently precise understanding of the relationship between the control values cyan, magenta, yellow, black, clear medium and white (CMYKCW) and the resulting colour appearance for many practical applications. This relationship is to be investigated both on the basis of the control values (CMYKCW tonal values) available in practice and for the concrete arrangement of the manufacturer- or driver-dependent voxel arrangement (if available).

This is especially true for the fundamental optical characterization or modelling as well as the visual plausibility and practice-oriented measurability, which is strongly determined by the application case of the 3D printing industry. A first application case is the determination of the necessary measuring parameters for the development or adaptation of colour measuring devices, a second is the limits of the use of established colour measuring devices for the characterisation of 3D full colour prints or, if necessary, their further development or, for example, the concrete integration of 3D printing profiles in Photoshop for a colour-accurate preview (soft proof).

Results

In this project, methods for improving colour management in graphic 3D printing were investigated and further developed. The analysis of the currently available control options showed three different variants. These are 3D printers that only offer RGB control and are therefore limited to a LookUp-based colour description. Here it could be shown that the profiling of concrete 3D printers improves the colour accuracy by up to 30% compared to the default printer profiles. For this purpose, a web application was programmed that enables the measurement of the new translucency parameter alpha.

In the second case, access to the device tone values and thus the basic colorants used is possible. This access extends the description by means of optical, i.e. phenomenological 3D printer models. With the help of machine-learning algorithms, the colour accuracy for established 3D printers (Stratasys J750, Mimaki 3DUJ-553) could be improved by a factor of 6 (with the same number of colour patches).

With full control of the material ratios in all voxels, i.e. the microstructure, the simulation of light propagation using physics-based 3D printer models showed unprecedented accuracy in predicting 3D-printed visual effects, especially colour and translucency. However, this simulation is not yet real-time capable even with current hardware acceleration. An application was also developed for this purpose, which illustrates the relationship between device tone values and final colour impression.

Meeting documents

| Title | Version | Date | File type | Download |

|---|---|---|---|---|

| PA meeting (agenda) | 5te | 19.05.2020 | Download | |

| PA meeting (minutes) | 14.02.2020 | Download | ||

| PA meeting (minutes) | 10.03.2020 | Download | ||

| Video recording from PA Meeting on 2020-05-19 | 26.02.2021 | youtube | Download | |

| Meeting Slides for PA meeting 2020-05-19 (1) | 03.03.2021 | Download | ||

| Meeting Slides for PA meeting 2020-05-19 (2) | 5te | 19.05.2021 | Download | |

| Meeting Slides for PA meeting 2021-03-1 | 01.03.2021 | Download | ||

| Video recording of PA meeting 2021-03-01 | V.1 | 01.03.2021 | youtube | Download |

Findings and publications

| Title | Version | Date | File type | Download |

|---|---|---|---|---|

| Deep learning models for optically characterizating 3D printers | 26.02.2021 | Download | ||

| 3D-Scanner profiling using AI (German) | 05.02.2021 | Download | ||

| Meeting Slides at PA meeting on 2021-03-01 | 01.03.2021 | Download | ||

| Simulation of bottom-up simulation vs. 45/0 measurements | 11.02.2022 | zip | Download | |

| Compatibility 3D-tools/ formats (Update 13.06.2022) | 13.06.2022 | Download | ||

| Perceptually Optimizing Color Look-up Tables | 04.05.2023 | Download |