Topic of your interest

The smart card market requires extremely high functional reliability. For this reason, manufacturers go to enormous efforts to simulate the aging and stress of a card in practice. The aim of the project is to provide the industry with a practical, fully complete and fast functional test. The results are also to be integrated into the standardisation work, as the current status of the relevant card standards is unsatisfactory at the beginning of the project with regard to the evaluation of card functionality. Either the functional tests defined in the ISO standards are too extensive to be integrated into process monitoring or extended investigations, or they are not sufficiently meaningful.

We know that there must be a correlation between the physical characteristics of a smart card and the functionality of its application interface. To address this application interface and to interpret its reaction, methods are to be developed which allow a real and fast functional test. The results of this project should help card manufacturers to improve their manufacturing process and to ensure the functionality of their smart card products in the required service life and under the given conditions of use.

Solution steps

It is important for the project that the selection of test samples (smart cards) represents the technologies used.

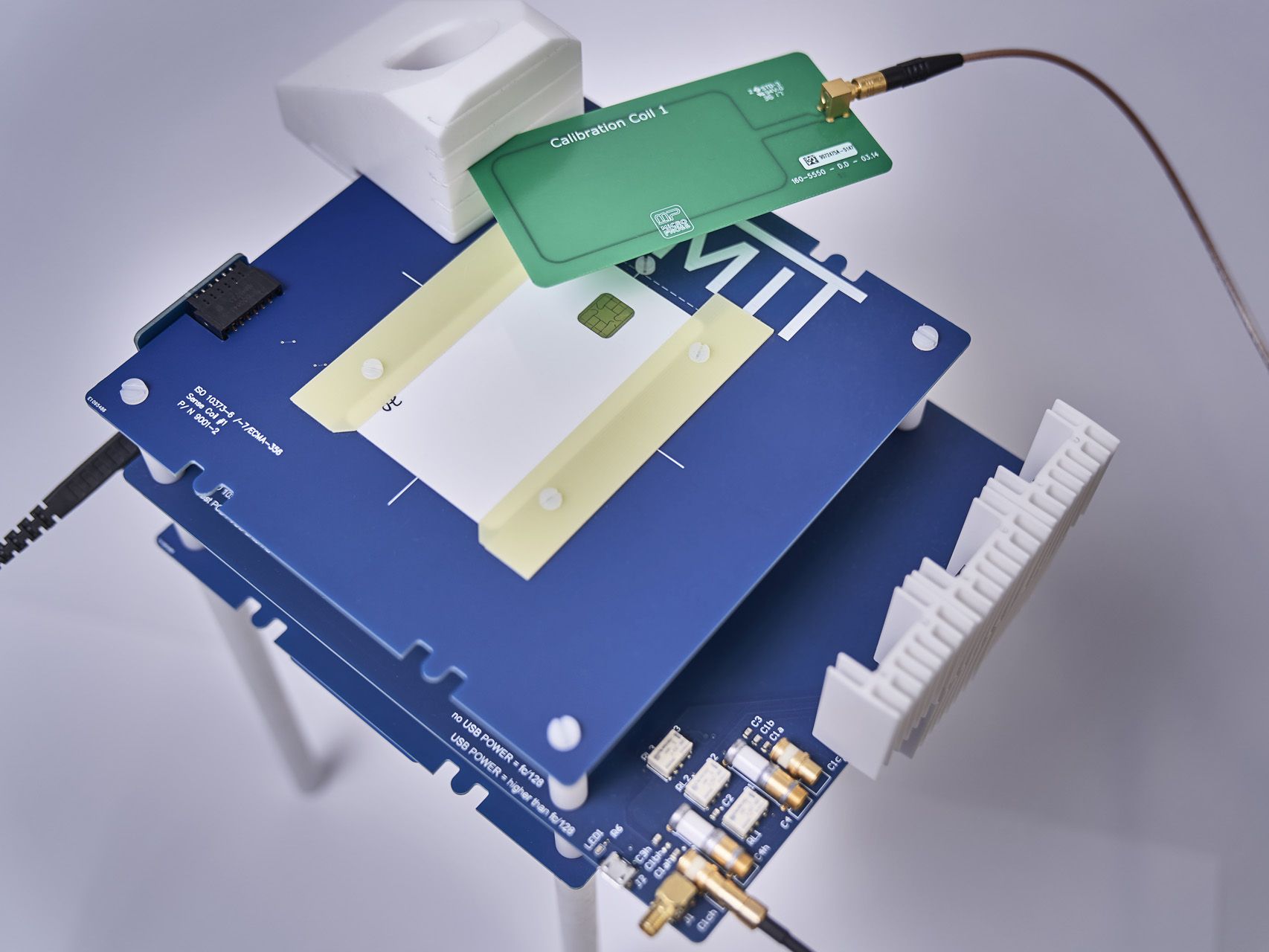

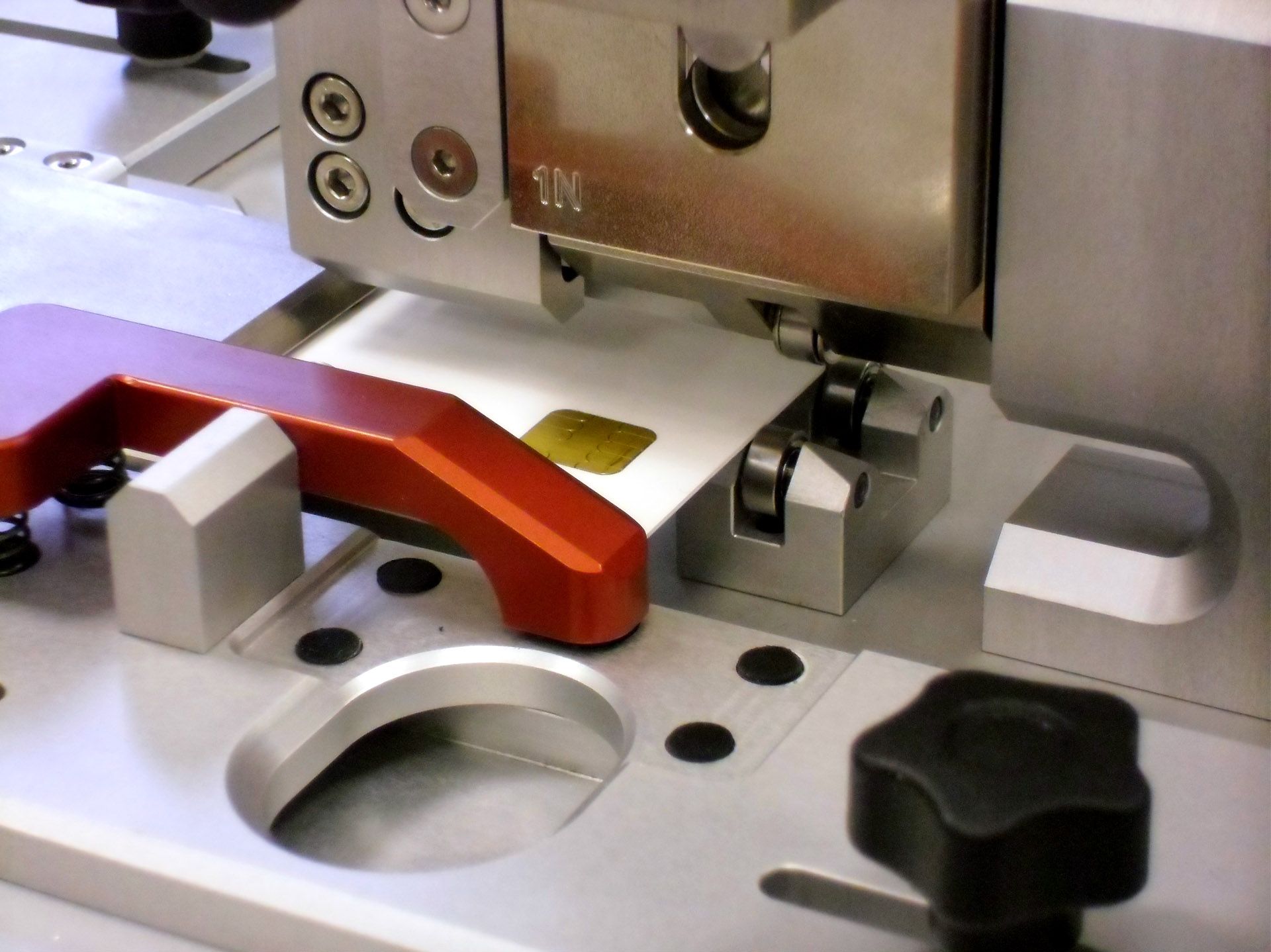

An initial characterisation serves as a fundamental basis for the subsequent analysis of possible correlations between the physical characteristics of the card and its application interface. The aim in each work package of the project is to capture as accurately as possible the structures and processes of communication between smart card and reader in the different response layers (OSI model).

In this way, every change in the response behaviour of a card can be recorded in detail. With the help of the test routines developed together with the chip manufacturers, the basis for the later, clear allocation of the physical, chemical and climatic influences on the response behaviour or the physical parameters of the smart cards is to be established.

Achieved results

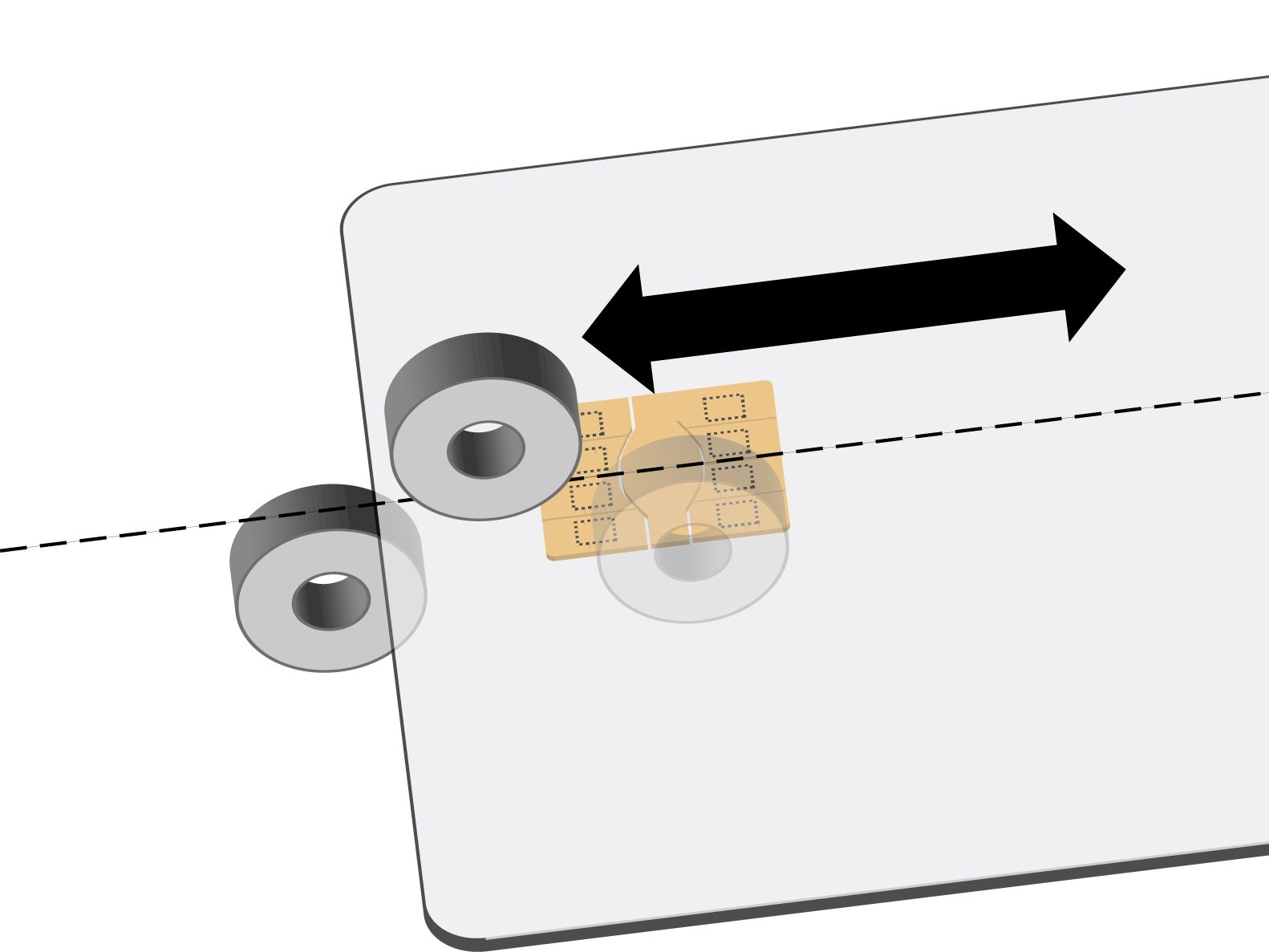

The investigations indicate that the detection of resonance frequency and quality enables a good characterisation of the function of contactless smart cards. Together with the developed test command the functional quality of the cards can be measured. The cards can thus be well characterised both in their initial state and in their states according to various exposure scenarios. The influence of physical, chemical and age-related stress – taking into account time factors – can also be simulated with the new methods.

Further analyses on specially manipulated cards have shown that it is possible to distinguish between different defects.

Due to the short test duration, the test command is suitable for a “100% check” on all produced smart cards in the context of process monitoring. The only requirement, however, is that a separate tolerance range is defined for each individually produced card. It is not possible in this context to define a global tolerance independent of the chip, antenna design and connection technology used.