Topic of your interest

Smart cards are often misunderstood in their complexity. As a user, you might think that you are using a simple piece of plastic, but this is not the case. A card consists of up to 16 layers, in which an antenna can also be integrated. Accordingly, determining the mechanical resistance over the lifetime of smart cards is an extremely complex task. The aim of this project is to improve a method for the cyclic bending stress of cards. This measurement technique should make it possible to quantify the resistance of cards using defined parameters.

The project results should assist the industry in improving its manufacturing process and ensuring the resilience of its smart card products in the required service life and under given application conditions.

By contributing the research results to the standardisation work, a qualitative comparison in tenders will also be possible.

Solution steps

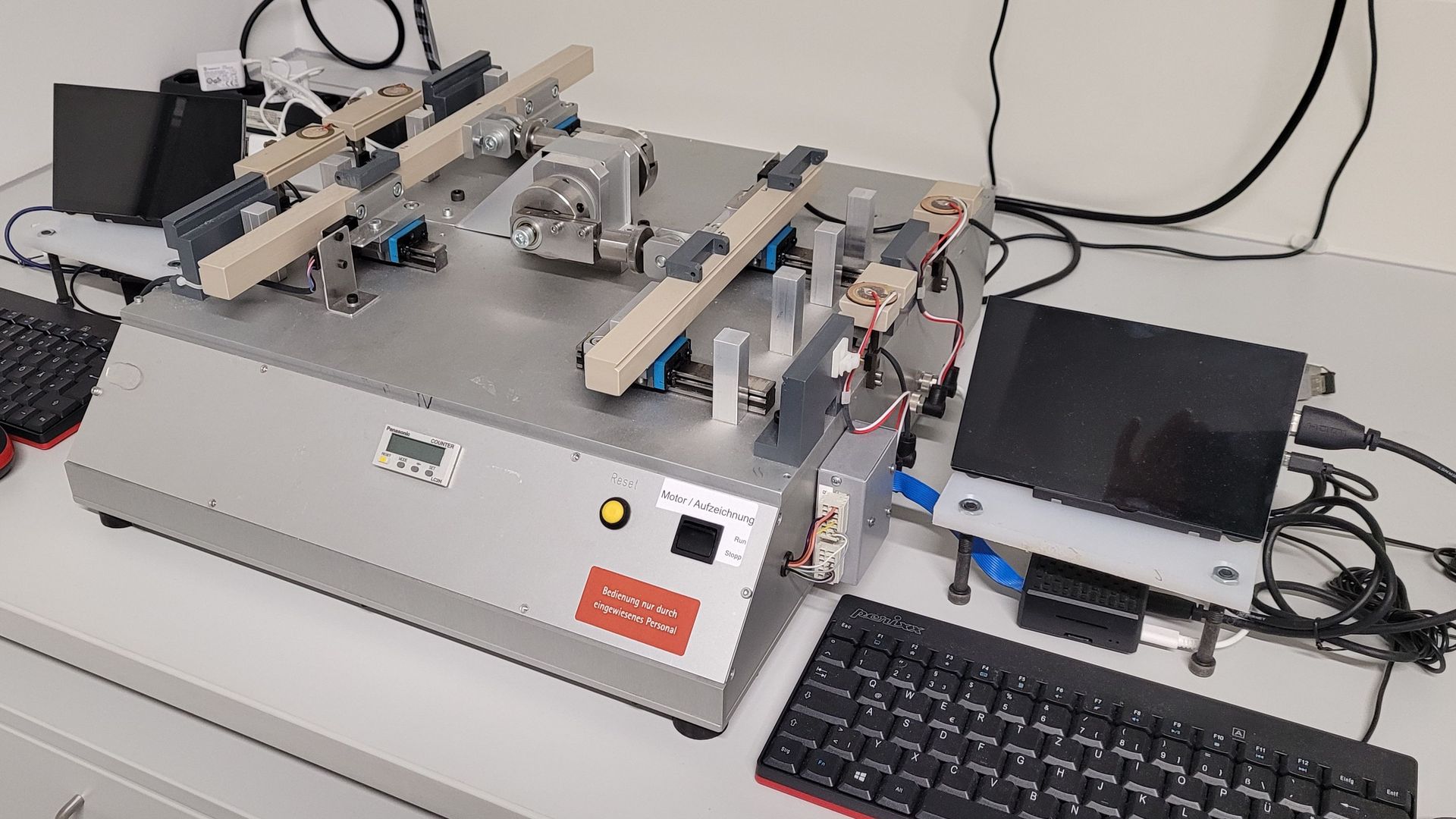

A testing device is developed which can expose card test samples to defined bending loads, measure the corresponding recovery forces and vary both bending frequency and bending amplitude. Optical, acoustic and electronic analyses are also possible in this way. The aim of electronic monitoring is to detect impairments (e.g. of the electronic chip function) as early and reliably as possible depending on the number of bending cycles. The temporal force progression is clearly described in terms of a mathematical model with influencing variables from the optical and electronic indicators and, if necessary, other material parameters.

The load analyses are carried out using programmed algorithms. Correlations between the data collected in the progress of the project and conventional indicators are established and evaluated. Since the newly developed test and analysis method will provide much more information than conventional stress tests, it will also be investigated how this information can be used to evaluate the stress resistance of cards and applied in the form of new key parameters.

Results achieved

In the research project, a test method was developed with which the mechanical resilience of chip cards can be evaluated using metrologically determined parameters. This involves a dynamic bending load in which the cards are bent cyclically until the material fails. Various physical parameters are measured continuously during the stress. These include the restoring force of the chip card, which it exerts against the deformation caused by the bending. The resonant frequency and the quality of the resonant circuit integrated into the card body are also recorded. The structure-borne sound of the chip card, which it transmits to the bending test device, is also measured.

Clear parameters could be defined for the measured course of the restoring force, which characterize the condition of the card body very well. This makes it possible to identify the individual phases of material failure. The individual values of these parameters were based on a so-called Weibull distribution. This made it possible to obtain new parameters that can be used to make statements about the failure risk of chip cards and their service life. This provides the industry with a reliable test method with which it is possible to compare the robustness of different chip cards.