Topic of your interest

How does mineral oil get into chocolate?

Mineral oil components in recycled paper and cardboard that can pass into packaged food are under discussion. The German Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU) responded by tendering this issue as a research topic through the German Environment Agency (Umweltbundesamt, UBA). The challenging project has come to an end, and we look back on many years of successful research work. The UBA report (German version with English summary) is available free of charge.

Research project: How it all began

Chocolate fans were concerned when allegedly harmful mineral oil was found in chocolate from Advent calendars. “Stiftung Warentest” had reported on this in autumn 2012. It was supposed that this contamination comes from the packaging. The cardboard boxes are made from waste paper and thus contain residues of (newspaper) printing inks containing low-grade oil, which get into the food directly or via the air, according to the reasoning. The consumer platform “Foodwatch” issued warnings in the following years, too. Tests showed positive results not only in chocolate, but also in many other foods, e.g. baby food.

Even though there is no scientific evidence whether the small amount of mineral oil is actually hazardous to health and what different sources of mineral oil exist (e.g. sisal/jute sacks and harvesting machines), Fogra was assigned by the German Environment Agency to further develop mineral oil-free printing inks and to test the practical application in newspaper printing.

Project start: Defining goals

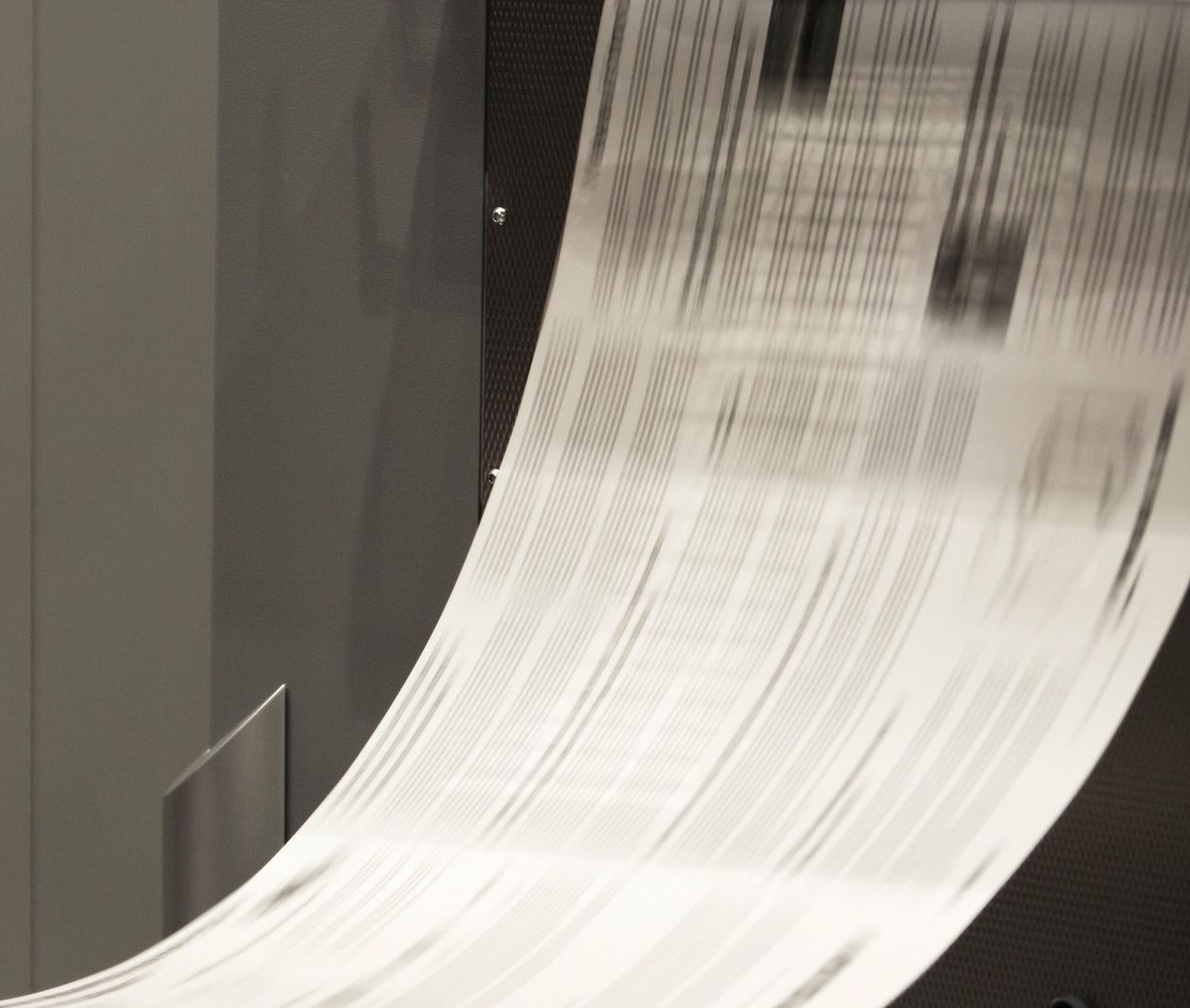

The project started in 2016. The objective was to develop new mineral oil-free printing inks for newspaper printing (such inks did not exist for this purpose until then!) and to test these inks both in the laboratory and in practice. The decisive factor here is that the printing inks in newspaper printing plants have to work in continuous operation without causing printing problems or quality losses.

Requirements: Practicality and recyclability

Within the project’s scope, two mineral oil-free or mineral oil-optimised ink systems for newspaper printing were to be developed and tested in the laboratory and practice. The top priority was to guarantee practical suitability for continuous use in printing plants while complying with existing quality requirements. Regarding the ink formulation, the printing inks were required to conform to the “Blauer Engel” eco-label. As a result, the entry of mineral oils into the recycling process of paper shall be reduced in the long term. This goes hand in hand with the fact that newspapers that are produced with the new inks can be deinked and thus recycled so that the waste paper stream is not endangered. Furthermore, mineral oil content determinations were carried out according to the BfR method. This was to predict the mineral oil content to be expected later in random samples in the field.

The most important factor: Successful partnership

Reliable partners were essential for the practice-oriented research project, which was completed in December 2020. Fogra worked together with ink manufacturers and the Frankfurter Societäts-Druckerei (FSD). The Saxon Institute for the Printing Industry (SID) and the cardboard manufacturer Moritz J. Weig as well as the Department of Paper Manufacturing and Mechanical Process Engineering (PMV) at the Technical University of Darmstadt also supported the project.

Sustainable research: Long-term print tests

The requirements for the first printing tests with the newly developed mineral oil-free newspaper inks were material compatibility, especially with the roller materials, and suitability for printing.

After the development of inks, Fogra staff tested them in the lab and in short print runs — both on Fogra's sheet-fed offset press and in the FSD. As is so often the case with new developments, multiple reworking was necessary. In the end two ink manufacturers were able to successfully present one ink set each. Both ink series met the requirements, so that the first long-term trial could start in July 2018. In the course of these trials, real newspapers were printed in the FSD during production and with each ink set over a period of three months.

In the follwing months, the trials had to be stopped several times because the inks changed over time and the required print quality and a smooth process during printing could not be maintained. Reworking and improvements were necessary. Parallel to the printing tests, samples were repeatedly taken and examined for their deinkability and mineral oil content. During a three-month period with a mineral oil-free ink series, the discharge of mineral oil from previous inks from the press could be verified. At the end of the project, both ink series could be used without having to stop the tests prematurely for printing reasons.

Successful project conclusion: Mineral oil-free newspaper inks

Within the framework of the research project, mineral oil-free newspaper printing inks that work in practice were developed. Due to efforts, e.g. in the EU, to make mineral oil-free printing inks mandatory, the demand for corresponding coldset inks is growing. Fogra has therefore taken up this issue at an early stage in order to be able to support printing ink manufacturers. “Be prepared” is the key message.

In this project, many players have made a decisive contribution to its success: representatives of all the important associations, printers, ink manufacturers, suppliers and the German Environment Agency. The cooperation was essential and has resulted in a successful project conclusion. Specials thanks go to all parties involved.