Topic of your interest

Testing of labels

We are FINAT listed. In addition to the test methods of FINAT, AFERA and PSTC, we also test adhesive labels and tapes according to individual standards. Whether paper or plastic based, office product or vehicle mounting - self-adhesive materials must comply with the manufacturer's specifications and be suitable for the intended purpose (removable, permanently adhesive). The release properties of the release material must allow industrial processing. We will be pleased to support you in these and other issues.

Your benefit

To have us test your products is right from the beginning: You save time and money, get everything from one source, benefit from a fast and reliable service and receive the results after a few days.

Through our quality and standardscompetence, you do not have to invest time in time-consuming standard research and its implementation. We are always up to date and can also make statements for future generations of standards.

A selection of our label tests:

Adhesion to glass or steel (peel angle 90° and 180°)

Release force slow/fast

Shear strength static/dynamic

Adhesive or silicone application weight

Resistance to low/high temperatures, UV radiation and chemicals

Punching accuracies

Dimensional accuracy

Contact person

Can we support you with your label topics? Contact me without obligation to discuss everything else!

What you need to do

For example, you have two labelsmaterials, which by manufacturerspecification both should be removable. In practical application, however, only one material proved to be removable, although the substrate was the same in both cases.

Our procedure

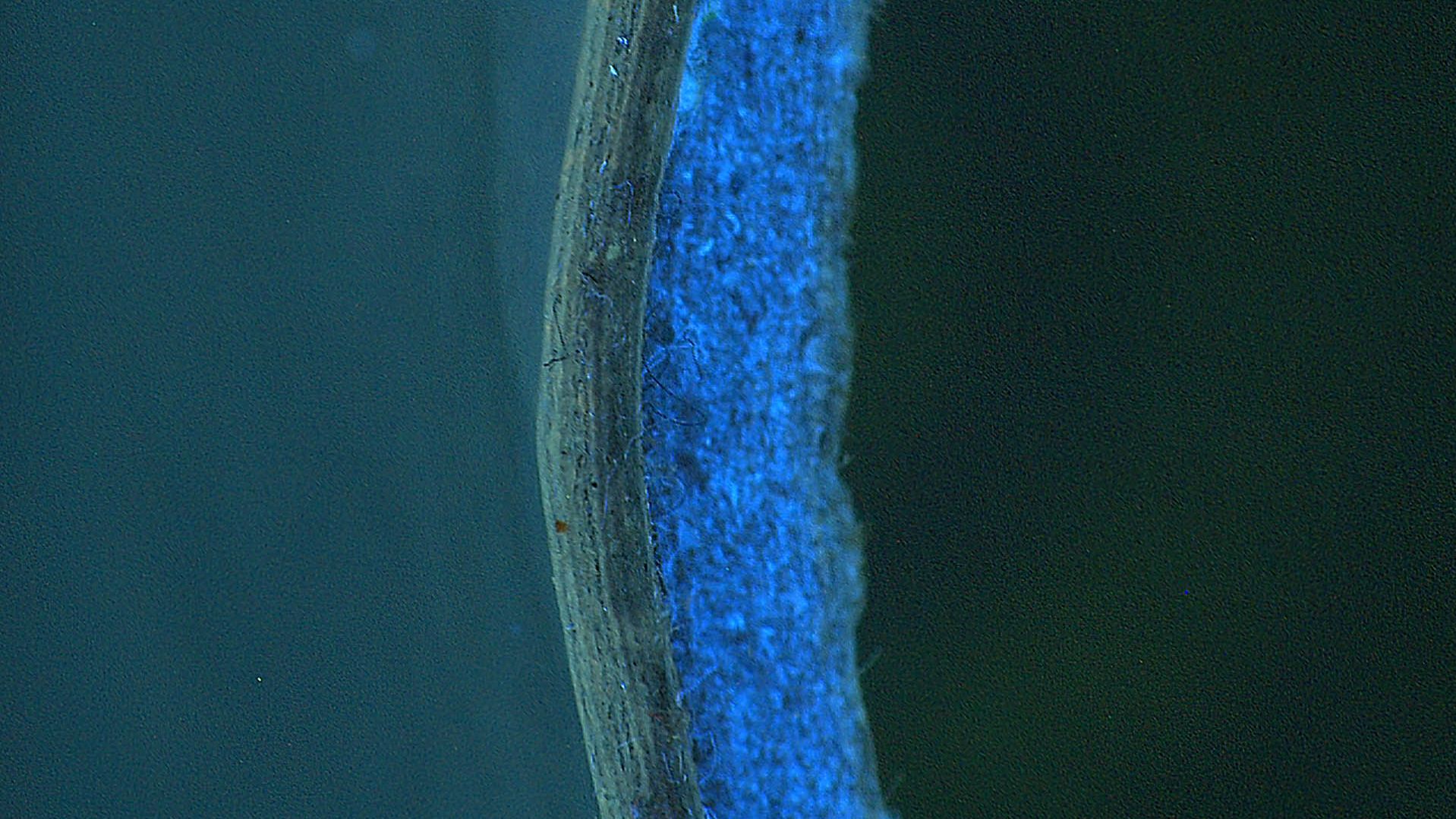

You provide us with samples of both label materials for testing the adhesive strength according to FINAT FTM 1. We cut ten 25 mm wide test strips each in machine direction from the material and, after conditioning, we stick them onto glass plates and press them tight with a pressure roller. On a calibrated material testing system, the adhesive strength test is performed with a peel angle of 180° after two specified waiting times (20 min and 24 hours). The adhesive strength is determined as the average value of the tested test strips and is compared with the specifications for removable pressure-sensitive adhesives (< 8 N/25 mm) compared. The fracture pattern is described as specified. In the case of removable adhesives, there must be no residues on the glass plate after the test.

Our offer

Testing of adhesion according to FINAT FTM 1 on two types of adhesive material:

343.70 € (Fogra-Member) | € 491.00 (normal)

I would be pleased to provide you with a non-binding offer for your label inspection: