Topic of your interest

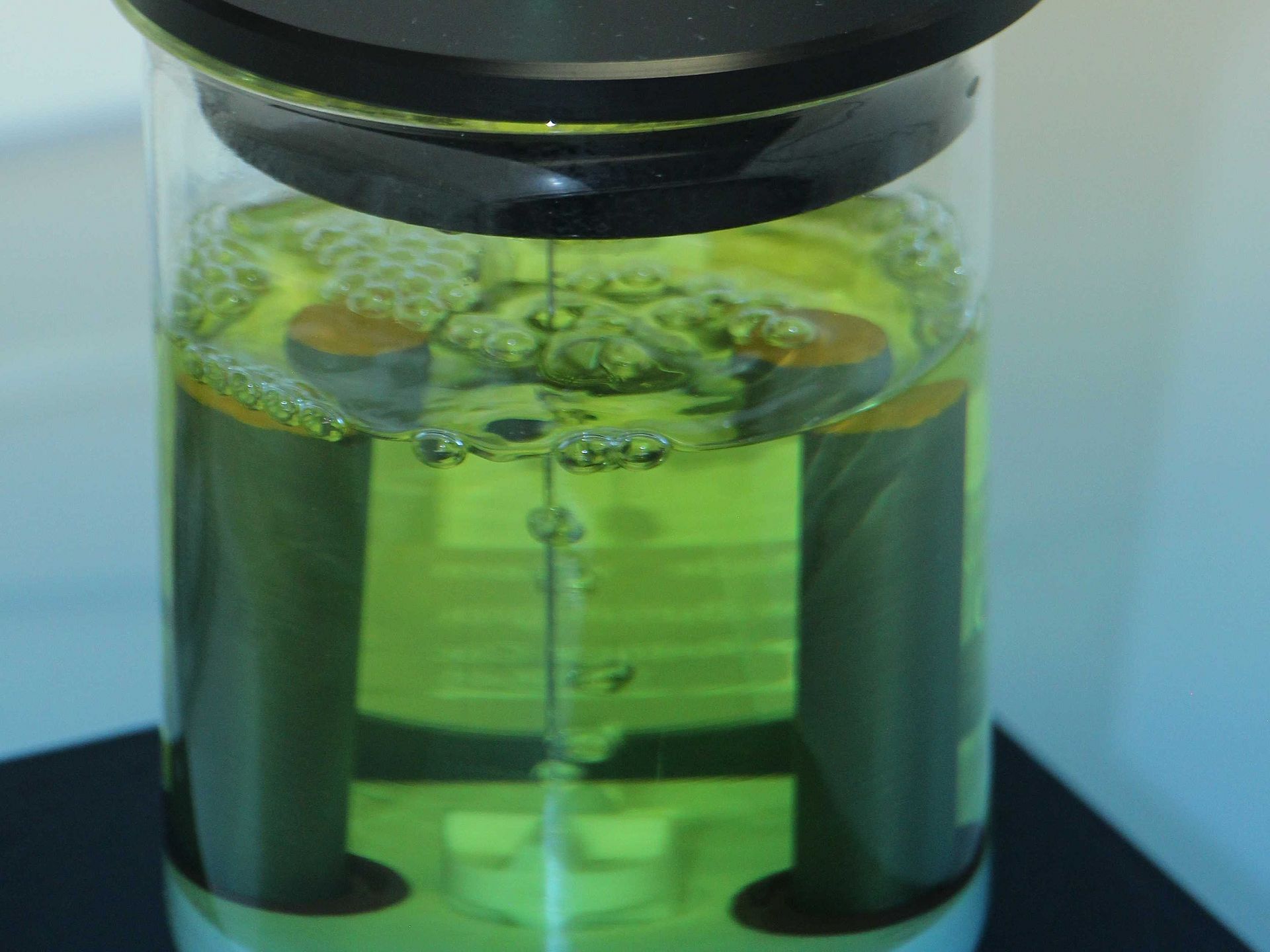

The research project will examine whether the standard method currently used for corrosion testing of dampening solution additives can be replaced by a time- and thus cost-saving electrochemical method.

Furthermore, the influence of different water qualities on both the printing behaviour and the corrosiveness in the printing press is being investigated.

Solution steps

Several steps are necessary to achieve the goal of the research project:

- Introduction of impedance spectroscopy and noise analysis

- Correlation of the results from the new measuring methods with the mass removal rates of known measuring techniques

- Influence of different water parameters on the results of the corrosion test

- Water hardness

- Buffer systems

- Biocides

- Corrosion inhibitors

- Effect of the water parameters on the printing behaviour

Achieved results

On the one hand, the results of the research project show that currently no rapid electrochemical method such as impedance spectroscopy and electrochemical noise analysis is available to reliably replace the time-consuming but established standard method for corrosion testing.

There is no correlation between the new procedures and mass removal rates.