Topic of your interest

Metallic effects are often used in packaging. Communication of these effects is problematic in the workflow from product planning to the actual printing process. So far, there are no production-oriented parameters that allow a clear description of the visual appearance. In addition, both the colour measuring devices commonly used in the printing industry and the viewing booths are unsuitable for characterizing metallic print samples.

Solution steps

Colour measurements with different measuring devices and geometries are to be carried out on an extensive selection of metallised print samples. For this purpose, multi-angle colour measuring devices, a goniospectrophotometer and a spherical measuring device are to be used. Additionally gloss measurements are carried out.

Furthermore, a special viewing device with adjustable illumination and viewing angle is to be constructed. The visual evaluations of the metallic samples achieved with this device are to be compared to the metrological results.

Achieved results

It turned out that the angle-dependent measured value curves of the tristimulus value Y on the metallic samples can be adapted very well by superimposing two exponentiated cosine functions. One of the two summands describes a narrow peak with high reflection and a maximum at the specular angle, while the other describes a comparatively broad peak with comparatively low reflection and a maximum at positive effect angles. They can be understood as the specular and diffuse portion of the reflected light.

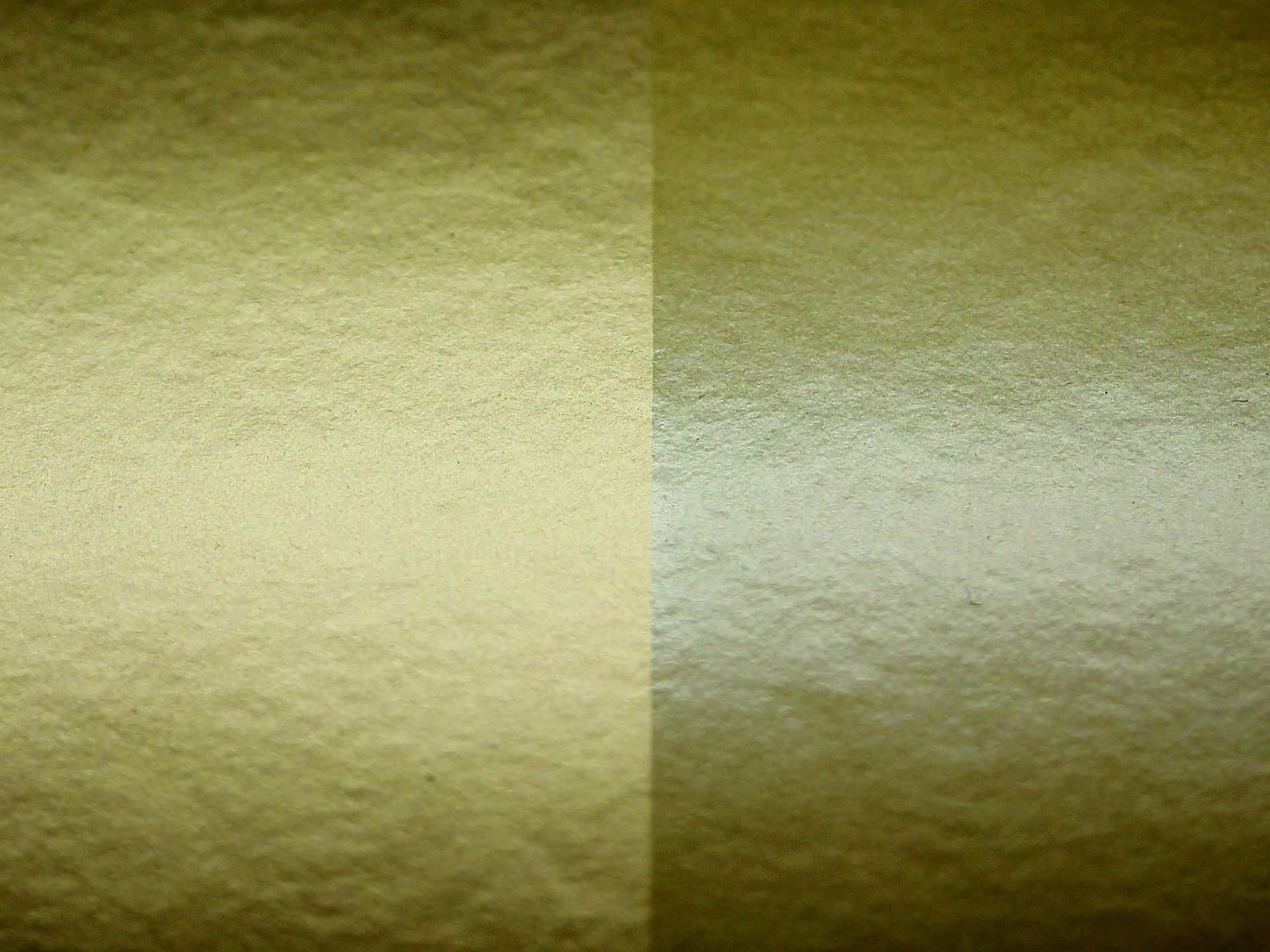

For the silver samples, the maximum brightness measured with the goniospectrophotometer shows a good correlation with the perceived metallic effect. This increases with increasing brightness. In the case of gold, the angle-dependent colour shift and the half-value width of the brightness must also be included. The former can be described with the help of the course in the u'v' chromaticity diagram. In this case, large colour changes lead to a devaluation of the metallic effect. High half-widths, on the other hand, cause an enhancement.