Topic of your interest

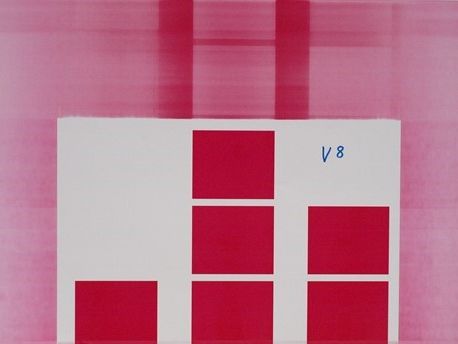

The deposits outside the paper format known as

Solution steps

The research project aims to gain a better understanding of the mechanisms of “Picture Framing”. By identifying the essential influencing parameters and their metrological determination, targeted remedial measures are to be established. Special attention will be paid to the moisture balance, which will be examined for the first time for detailed correlations with the phenomenon. It can thus be assumed that this is a key variable both in terms of the origin and possible reduction of the disturbing build-up.